|

BAIHP

Research: A. Manufactured Housing Research Cont'd

- Zero Energy Manufactured Home (ZEMH)

Nez Perce Fish Hatchery, Idaho

Category

A, 1 home

|

Figure

57 Zero Energy

Manufactured Home,

on site at the Nez Perce Fish Hatchery |

BPA,

working with BAIHP staff in Idaho and Washington, provided

funding for the most energy efficient manufactured home

in the country. The RFP was sent to 18 Northwest manufacturers;

Kit HomeBuilders West of Caldwell, Idaho was selected as

the manufacturer of the home. BAIHP staff solicited 24

industry partners to provide energy efficient building

components, including Icynene wall, floor and roof insulation,

a low-cost HUD-approved solar system, sun-tempered solar

design, and Energy Star© windows,

appliances and lighting. Partners include Building America

Team members such as Flexible Technologies, Icynene and

LaSalle. Complete list of specifications provided in Table

29.

The ZEMH (Figure 57) was built in the Fall

of 2002 along with a control home. The ZEMH was displayed

at the 2002 Spokane County Interstate Fair before siting

at the Nez Perce tribal fish facility near Lewiston Idaho.

Blower door and duct leakage tests at the plant and on-site

indicate that this is the tightest home ever tested by

BAIHP staff.

Working with FSEC and BPA, BAIHP staff installed monitoring

equipment for the ZEMH. Monitoring began in the 2003

and includes the following:

- Total electric use from grid

- Resistance elements in heat pump

- Heat pump compressor and fan motors

- Water heating equipment, including gallons used

- PV energy production (ZEMH)

Table 29 Zero Energy Manufactured

Home (ZEMH) and Base Case Home (Control) |

Component |

ZEMH |

Base |

Wall Structure |

2x6 ft, 16 in on center |

Same |

Wall Insulation |

R21 foam-spray |

R21 batt |

Floor Structure |

2x8 ft, 16 in on center |

Same |

Floor Insulation |

R33 (R22 Foam + R11 batt) |

R33 Blown Cellulose |

Vented crawl space wall |

R14 foil faced foam |

None |

Roof/Attic Structure and

Finish |

16 in on center

40 lb

roof load

4/12 pitch metal roofing

|

24 in on center

Standard

30 lb roof load

Same pitch and finish

|

Roof/Attic Insulation |

R49 foam |

R33 blown cellulose |

Window/Floor area ratio |

12% |

Same |

Windows |

Vinyl Frame, Argon filled,

low-e, Energy Star Approved |

Same |

Window Shading |

Dual blinds, heavy drapes,

awnings |

Single blinds, light drapes |

Doors |

U=0.2 metal, foam w/thermal

break |

Same |

Solar |

Solar ready design (mounts,

flashings and electrical chase)

4.2 kW peak rated PV

system with a 4 kW inverter and 12 kWh battery array

|

None |

HVAC |

2 ton unitary air-source

heat pump

12 seer, 7.8 HSPF

|

Same |

Zone heat |

150 W Radiant Panel in

kitchen |

None |

Ducts and cross over |

R8 crossover

Flex Flow

crossover system

Mastic with screws

More efficient duct design

|

R8 crossover

Sheet metal

elbows

Standard foil tape

|

Lighting |

100% Energy Star T8 and

CFL fixtures |

T12 and Incandescent fixtures |

Appliances |

Energy Star washer and

dryer, refrigerator, dishwasher |

Standard equipment |

Whole House Ventilation |

Heat Recovery Ventilator

w/HEPA, continuous operation (turned off in 8/04) |

Quiet (low-sone) Energy

Star exhaust fan, continuous operation |

Spot Ventilation |

Energy Star bath fans,

std. Kitchen fan |

Quiet (low-sone) bath

fans, std. Kitchen fan |

Ceiling Fans |

Energy Star with dimmable

CFL |

Standard with Incandescent

bulbs |

Domestic Hot Water |

PV controlled, active

anti-freeze solar water system, with 80 gallon storage,

and 64 ft 2 of collector area solar pre-heat tank (pre-plumbed),

40 gallon standard tank EF=0.93 |

EF=0.88 standard electric |

Air Sealing |

Wrap with tape flashing

Marriage line gasket (new product)

Penetrations sealed

with foam insulation

|

Wrap without tape flashing

Standard practice marriage line sealing

|

Air/Vapor Barrier |

Walls and Ceiling: Painted

Drywall

Floor: Floor decking

|

Same |

Data logger collects 15 minute data from wired sensors

and transmits daily to the host computer at FSEC via

modem. Summary data reports are available at www.baihp.org under “Current

Data.” Plug-type loggers were installed in mid

March 2003 to sub-meter the energy use of the refrigerator,

freezer and clothes washer in each home, as well as the

radiant heat panel and HRV in the ZEMH. Data from these

loggers was collected by occupant readings in mid-December

2003.

Preliminary findings

Measured

net energy use of the ZEMH 6% is lower than the base home,

not normalized for occupant behavior. This also does not

take into account the fact that the ZEMH’s PV system

was only fully operational for one month.

The ZEMH required 45% less space heating energy, possibly

due to improved building envelope measures, and the lack

of consistent HRV operation.

The measured envelope leakage in the ZEMH was 2.0 ACH50,

much lower than the base home (indeed, lower than any

other NEEM home tested in the field) and substantially

tighter than typical HUD code homes.

The ZEMH total duct leakage was 46% lower than the base

home; leakage to the outside was 405% lower than the

base home. The BAIHP staff speculates that the unprecedented

low leakage to the outside value is the result of the

ducts in the ZEMH being located within the conditioned

space, and effectively within the pressure envelope of

the home, surrounded as they are by foam insulation.

The solar water heating system in the ZEMH provides

most, if not all of the hot water needed during the summer

months, and roughly 45% of the total hot water demand.

The PV system with net metering provides 38% of the total

ZEMH energy use.

The

project highlights the importance of occupant choices and

behavior on the performance of energy efficient housing.

Based on the preliminary monitoring data and occupant surveys,

the behavior patterns of the ZEMH occupants are not themselves “energy efficient”.

These patterns create the appearance of a less efficient

home. On the other hand, the behavior of the ZEMH occupants

may shorten the payback for the innovative technologies

of the ZEMH.

BAIHP staff also performed a benchmarking analysis on

the ZEMH, as part of the overall benchmarking effort.

The ZEMH reached a level of 60% above the NREL prototype,

which indicates the difficulty of obtaining a high benchmarking

score.

In December of 2004, a research paper was presented

at BTECC which provided a preliminary evaluation of the

ZEMH performance without the full operation of the PV

net metering system. By the spring of 2006, there will

be a full year of ZEMH data, with the PV system operational.

- Manufactured

Housing Indoor Air Quality Study

Plant City, Florida, and FSEC MHLab

Papers: Hodgson, A.T., Apte, M.G., Shendell,

D.G., Beal, D. and McIlvaine, J.E.R. (2002a). Implementation

of VOC source reduction practices in a manufactured house

and in school classrooms. In Levin, H. (Ed.), Proceedings

of the 9th International Conference on Indoor Air Quality

and Climate. Indoor Air 2002, Santa Cruz, CA, Vol. 3.

pp. 576-581.

Hodgson, A.T., D. Beal and J.E.R. McIlvaine. 2002b.

Sources of formaldehyde, other aldehydes and terpenes

in a new manufactured house. Indoor Air12: 235-242.

Hodgson,

A.T., A.F. Rudd, D. Beal and S. Chandra. 2000. Volatile

organic compound concentrations and emission rates in

new manufactured and site-built houses. Indoor Air10:

178-192.

This is a summary of several indoor air quality (IAQ)

projects designed to improve the IAQ of manufactured

homes; specifically to find ways to reduce the formaldehyde

levels found in manufactured homes. This was a collaborative

effort of the Florida Solar Energy Center (FSEC), Lawrence

Berkeley National Laboratory (LBNL) and Palm Harbor Homes,

Inc. (PHH), a leading nationwide producer of multi-section,

high-end, manufactured houses with corporate offices

in Addison, TX.

In

1999 – 2000

a study was conducted to identify and verify the major

sources of formaldehyde, aldehydes, and terpene HCs in

a new manufactured house. Laboratory emission tests were

conducted with a number of wood and engineered wood products

and aldehyde and volatile organic chemical (VOC) measurements

were made in the house. Although only a single house was

studied, the information on sources is anticipated to have

broad application to residential construction due to the

widespread use of similar materials and building practices.

The manufactured house was typical of better quality

two-section houses produced in Florida. It was completed

in November 1999. Within three weeks of manufacture,

it was installed at a nearby site. The house was used

daily as a sales model. It was decorated, fully furnished,

but unoccupied. There were three bedrooms and two bathrooms.

The manufacturer supplied a detailed list of materials

used in the house. Between December 1999 and January

2000, ~30 specimens of the major materials were collected

from the production facility. These were cataloged, packaged

in aluminum foil, and shipped to the laboratory by airfreight.

The specimens were stored at room conditions in their

original packages until they were tested. Most materials

were tested within three months of collection. Measurements

were made after about a 3-week exposure, and area-specific

emission rates (i.e., emission factors) were calculated.

Air sampling in the house and outdoors was conducted

in March 2000. The house ventilation rate was quantified

concurrently by tracer gas decay. The ventilation rate

measurement and the VOC air sampling and analytical methods

for field and chamber work have been described previously

(Hodgson et al., 2000)

Whole-house emission rates for combined materials were

predicted based on the emission factors and the corresponding

material quantities. These predicted values were compared

to whole-house emission rates derived from measurements

of VOC concentrations and ventilation rates. For 10 of

the 14 target compounds, including formaldehyde, the

predicted and derived rates agreed within a factor of

two, which considering the uncertainties involved is

considered good agreement. The predominant sources of

formaldehyde in the house were bare particleboard (PB)

and medium density fiberboard (MDF) surfaces in the cabinetry

casework and molded high-density fiberboard doors. The

plywood subfloor under the carpet was a smaller source

of formaldehyde and the major source of higher molecular

weight aldehydes and terpene hydrocarbons.

As the result of this study, recommendations were developed

for reducing concentrations of formaldehyde and other

VOCs in new house construction (Hodgson et al., 2002a).

These are reproduced here in Table 30. The first

five recommendations are aimed at controlling or eliminating

important sources of formaldehyde. Other potential sources

of formaldehyde not addressed in the house study or in

the table include tack strips used for the installation

of wall-to-wall carpet and fiberglass insulation used

in wall, floor and ceiling cavities. Use of barrier materials

on the floor may result in moisture condensation problems

in hot-humid climates and possibly other situations and,

therefore, should be used with caution.

Table 30. Recommended

VOC Source Reduction Practices For New House Construction |

No. |

Source Reduction Practice |

1 |

When alternates exist, avoid wood products

with urea-formaldehyde resin system |

2 |

Construct cabinet cases with fully

encapsulated wood products |

3 |

Use frameless cabinets to eliminate

MDF stiles |

4 |

Apply laminate backing sheet to undersides

of PB countertops |

5 |

Use alternate low-formaldehyde emitting

passage doors |

6 |

Apply barrier material over plywood

subfloor in carpeted areas |

In

2004 a pilot demonstration project was conducted at PHH’s

production facility and sales office in Plant City, FL. The

project was originally conceived in 2002 as a side-by-side

demonstration of simultaneous improvements in energy performance

and IAQ to be achieved using existing technologies. The concept

was to build two houses, essentially identical with respect

to their size, floor plan, and major materials. One house

would have added features to improve energy performance and

IAQ. The other house would have no special modifications

and would serve as the control. They would be sited in a

residential community on adjacent, identical lots. Both would

have computer-simulated occupancy (i.e., controlled use of

lights, appliances, heating and cooling). Monitoring of energy

usage and performance and IAQ metrics would be conducted

over at least a one-year period. Finding the appropriate

residential site and the funds needed to cover the costs

associated with maintaining the houses at the site for a

year proved difficult. Consequently, the study plan was modified

in 2003 to reduce costs and take advantage of PHH’s

model home sales office in Plant City.

Approximately

on an annual cycle, PHH builds examples of their new houses

for display at their sales office. The houses present PHH’s

range of models and features. They are decorated and furnished,

but unoccupied. The houses are open to the public during

normal business hours seven days a week and their heating

and cooling systems are operated accordingly. The use of

these houses as study houses has some limitations. The

houses generally vary somewhat with respect to size and

floor plan, interior finishes and furnishings may vary, orientation

with respect to sun and wind may vary, monitoring instrumentation

must be kept out of sight, and sampling can only be conducted

outside of normal business hours. In addition, computer controlled

simulations of occupancy are not possible.

To the extent possible, the study plan was revised to accommodate

these factors.

In

June 2003, two model houses, then in the planning stage,

were selected for use in the project. A 1,440-ft2, double-wide

house designated as “Monte Carlo” was selected

to receive the energy and IAQ modifications. A 1,540-ft2

double-wide house designated as “Edison 2” was

selected to serve as the primary control house. The houses

were to be installed on nearby lots in the sales center in

approximately the same orientation.

The project participants early on developed specifications

for enhanced IAQ. These specifications were reviewed and

revised in June 2003 to reflect those energy and IAQ modifications

determined by PHH management to be relatively easily installed

on the production line and/or during installation. The revised

IAQ specifications are listed in Table 31.

Table

31 Revised IAQ Specifications |

Component |

Specification |

Cabinet Construction |

Use plywood face frame

material and vinyl-two-sides (V2S) particleboard for

all casework |

Countertops |

Construct all countertops

with V1S particleboard with vinyl surface on underside

of tops |

Carpeted Floors |

Install Tyvek (Dupont)

house wrap over plywood subfloor before installing

carpet. Use Nylon 6,6 carpet and synthetic fiber carpet

cushion (both CRI Green Label) |

Wall & Ceiling

Paint |

Use low VOC interior paints

(Sherwin-Williams Harmony brand) |

Passage Doors |

Use vinyl-coated doors |

Trim |

Use wood lumber trim throughout

house; avoid use of MDF trim |

Recessed Light Fixtures |

Install gasketed light

fixtures |

The two houses were produced in late July and early August

2003. Installation of the two houses was completed and the

heating and air conditioning (HAC) systems were operational

by the end of September. Not all of the originally planned

IAQ modifications (Table 2) were installed in the Study house.

Standard molded high-density fiberboard, passage doors were

used, as the door manufacturer no longer produces vinyl-coated

doors. Medium-density fiberboard (MDF) was used for the face

frames of the cabinets because PHH did not have sufficient

stock of the plywood material. Standard tack strips with

unquantified emissions of formaldehyde were used for the

carpet installation, as LBNL was unable to identify an alternate

with low formaldehyde emissions.

Energy Gauge ratings of the experimental house (Monte Carlo)

and the control (Edison) showed that the control house was

an Energy Star home, scoring 86.5, while the experimental

house was a Building America house, scoring 91.1. There were

many obstacles to successfully retrieving data from the houses,

but available results show that the BA house saved about

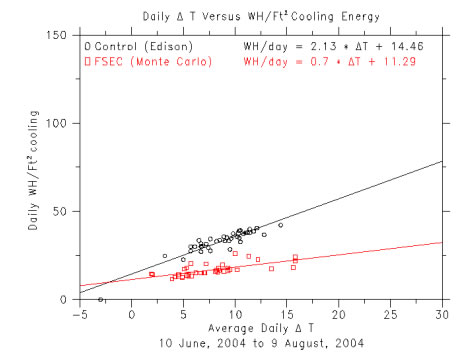

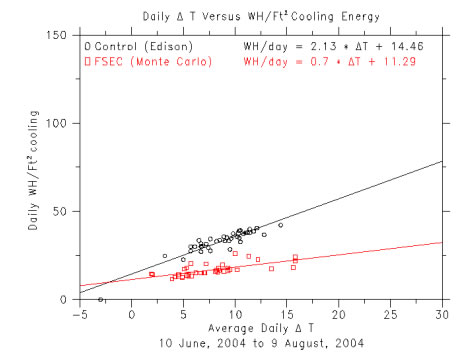

50% more air conditioning energy than the control house. Figure

58 illustrates this. The plot normalizes the data by

plotting the daily air conditioner energy use pre ft 2 of

conditioned space versus the average daily temperature difference

between the inside and the outside (Average Daily )T).

Figure 58

IAQ work started with an initial set of active air samples

for VOCs and aldehydes collected outdoors and in the Study

and Control houses on December 11, 2003, approximately

2.5 months after the houses were fully operational. The

second set of active samples was collected three months

later on March 2, 2004. Passive aldehyde samples were obtained

in the Study and Control houses and in an additional triple-wide

house of the same age over four one-week intervals between

these dates.

There were some distinct differences between the concentrations

measured in the two houses. Notably, the concentrations

of formaldehyde in the Study house were about three times

higher than concentrations in the Control house. This difference

was not anticipated based on the source reduction measures

aimed at lowering the emissions of formaldehyde in the

Study house.

Based on previous laboratory measurements of formaldehyde

emissions from interior components, we anticipated a minimum

25% reduction in the formaldehyde emission rate in the

Study house relative to the Control house. This was anticipated

due to the use of fully encapsulated particleboard for

the cabinetry casework, a diffusion barrier on the undersurface

of the particleboard countertops, and the weatherization

barrier applied over the plywood subfloor (Hodgson et al.,

2002b). We additionally expected the difference to persist

over the course of a year. The two-fold higher formaldehyde

emissions in the Study house prompted us to abandon our

original plan of quarterly measurements and instead to

focus on identifying the unexpected source of formaldehyde

emissions in this house. Firstly, FSEC and PHH staff jointly

inspected the houses. This inspection confirmed that the

intended formaldehyde source reduction measures had been

implemented in the Study house.

Two

other potentially relevant differences between the houses

were known at the time. Due to the energy efficiency

specifications for the Study house, a different manufacturer

than the HAC system in the Control house produced the

HAC mechanical system in the house. Secondly, some furniture

believed to be solid wood had been newly purchased for

decoration of the Study house. Older furniture taken

from PHH’s stock was used

to decorate the Control house.

In July 2004, the potential for the HAC systems to emit

formaldehyde was investigated. Each system is located in

a closet near the central living area. Active sampling

for formaldehyde was conducted in each house. The differences

between the return and supply measurements were small,

about plus 3% for the study house and about minus 8% for

the control house. These differences are within the uncertainties

of the measurements and, therefore, are not significant.

Another

inspection revealed that some of the backsides and undersurfaces

of the new wood furniture were fabricated from particleboard,

a typically high formaldehyde emission source (Kelly

et al., 1999; Hodgson et al., 2002b). Due to delays imposed

by PHH model center needs and 2004’s

hurricane season, in December 2004, approximately

14 months after the furniture was first delivered, we

located the furniture pieces in a storage garage. From

one accessible piece, we obtained 4.4-cm diameter specimens

of 3-mm thick particleboard using a hole-saw. Specimens

of 13-mm thick particleboard were similarly collected

from a furniture piece that was several years old and

was used in the sunroom of the house.

The emissions of formaldehyde from the two specimens of

furniture particleboard individually were measured in the

laboratory using small-scale environmental chambers as

described by Hodgson et al. (2002b).

From

the purchase requisition and the company’s

sales literature it was determined there were eight

new pieces of living room and master bedroom/retreat

furniture that likely contained some particleboard. The

total exposed surface area (one side) of particleboard

in these pieces was estimated to be 8.5 m2. Thus, the

estimated formaldehyde emission rate attributable to

the new furniture was about 80% of the total formaldehyde

emission rate derived for the house in December 2003.

Based on the formaldehyde emissions from the particleboard

from the older furniture, it is likely that the formaldehyde

emissions attributable to furniture would have been substantially

lower if older furniture pieces had been used.

This study did not progress as originally intended, and

the results did not conclusively show the efficacy of low-cost

measures intended to reduce the sources of formaldehyde

in the Study house. However, it is likely that the source

of the elevated formaldehyde emissions was correctly identified

to be a component of the new wood furniture installed in

this house and not in the Control house. If one-half the

estimated formaldehyde emission rate from the new furniture

(i.e., approximately the difference between the emissions

from new and old furniture particleboard) is subtracted

from the whole-house emission rate, the formaldehyde emission

rate in the Study house is nearly equivalent to the rate

in the Control house.

A formaldehyde concentration of 50 ppb and below has been

suggested as a reasonable target for new houses (Sherman

and Hodgson, 2004). The source reduction measures directed

toward other VOCs were successfully demonstrated. The use

of the weatherization barrier applied over the plywood

subfloor in the Study house appeared to function as predicted

to reduce the emissions of higher molecular weight aldehydes

and terpene hydrocarbons from this source, and the use

of the low VOC interior paint reduced the emissions of

a major VOC component associated with latex paints.

Data

collection was curtailed by the onset of 2004’s

hurricanes, three of which impacted Plant City, and

sales activity resulting in houses moving. The collected

data did show that the energy goals established for the

house were met, with a 50% reduction of energy use for

air conditioning compared to the control house.

- Manufactured

Housing Laboratory - Ventilation Studies

FSEC, Manufactured Home Laboratory

Paper:

Moyer, Neil, Chasar, Dave, Hoak, Dave, Chandra, Subrato, "Assessing

Six Residential Ventilation Techniques in Hot and Humid Climates," Proceedings

of ACEEE 2004 Summer Study on Energy Efficiency in

Buildings, American Council for an Energy Efficient

Economy, Washington, DC, August 2004. (Also available

online at www.baihp.org under Current

Data and Publications)

Ventilation Study

|

| Figure 59 Manufactured Housing Laboratory

at FSEC (above and below) was site for study of

six residential ventilation systems. |

|

The MHLab (Figure 59) is

a research and training facility of 1600 ft 2. This Energy

Star® manufactured

home has two separate heating and cooling systems:

- An overhead duct system connected to a package unit

air conditioner with electric resistance heating.

- A floor-mounted duct system connected to a split

system air conditioner, also with electric resistance

heating.

Only the floor mounted duct system was used in these

ventilation experiments.

Introduction

Ventilation is a HUD code requirement. The goal of ventilation

is to add fresh air to the home. This may be accomplished

by supplying outside air to the house or mechanical system,

exhausting air from the house (which consequently pulls

air into the house through joints in the walls, floor,

and ceiling), or a combination of the two.

Supply based ventilation tends to slightly pressurize

the home whereas exhaust based ventilation does the opposite

slightly depressurizing the house. The disadvantage of

supply based ventilation is that it forces conditioned

air into the floor, wall, and ceiling cavities, possibly

leading to condensation or mold growth in cold climates

and during the heating season. Likewise the disadvantage

of exhaust systems is that they pull unconditioned outside

through the floor, wall, and ceiling cavities into the

conditioned space, possibly leading to condensation,

mold growth, or uncomfortably high indoor humidity levels

in hot and hot-humid climates and during the cooling

season. The six residential ventilation strategies evaluated

are described in Table 32.

Table

32 Ventilation Strategies Studied in the MHLab |

Case

(Name)

|

Strategy |

Description |

# 1

(None). |

No mechanical ventilation |

Base Case scenario included only

the heating and cooling system of the home with no

outside air (OA) ventilation. |

# 2

(Spot) |

Spot ventilation (exhaust only) |

Bathroom and kitchen exhaust fans.

Operation scheduled for 30 minutes after a simulated

moisture producing event such as a shower or oven

use. |

# 3

(OA)

|

Outside air (supply based) |

Dedicated, filtered outside air duct

to return plenum when the heating or cooling system

is operating. Quantity of ventilation air provided

depends on air handler run-time. |

# 4 (Dehumid) |

Outside Air plus 10/20 Cycle and

Dehumidification (Supply Based) |

Same

as #3, except with an added air handler fan controller

(10-minute “on” -

20-minute “off” minimum duty cycle).

Provides scheduled ventilation when no cooling or

heating is called for. A stand alone room dehumidifier

(set to approximately 50% RH) located in vicinity

of the return air grill. |

# 5

(10/20 Cycle)

|

Outside Air plus 10/20 cycle (Supply

Based) |

Same as #4, except without the room

dehumidifier. |

# 6 (ERV1) (ERV2) |

Energy recovery ventilator (ERV1,

ERV2) |

Two different enthalpy transfer media

were used. Outside air was drawn in through the ERV

at a rate to meet the ventilation requirements. |

# 7

(Hstat)

|

Outside Air plus Humidistat (Supply

Based) |

This is a modified air handler fan

speed control. When dehumidification is needed, the

air handler fan is operated at lowest speed for enhanced

latent control. A higher speed is selected when sensible

cooling is needed. Ventilation air supplied via an

outside air duct, with air handler fan operation

controlled as in #4. |

House Operation and Experimental Procedure

Occupancy Simulation: Automated, computer controlled

devices, such as appliances, showers, and lighting, simulate

the sensible/latent heat generation and carbon dioxide

(CO 2) production of a family of four persons with periodic

showers, cooking and cleaning.

The

simulated latent occupancy load from breathing, bathing,

cooking, and laundry was achieved by adding 14 to 15

pounds of water per day based on documentation of "average" household

operation based on ORNL research conducted by Jeff Christian.

Water vapor was injected into the space using a vaporizer

at a rate of approximately 0.4 lbs per hour continuous

and an additional 0.4 lbs per hour during the evening

hours.

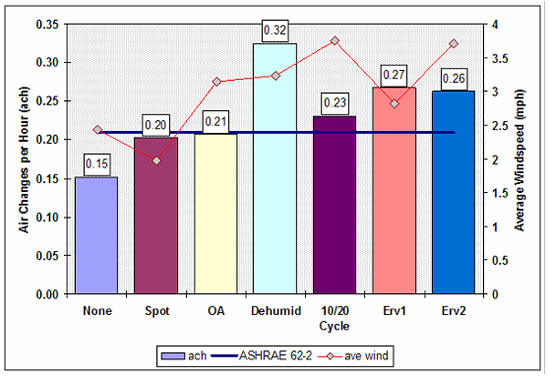

Ventilation Rate: Researchers conducted whole

house air tightness tests using sulfur hexafluoride as

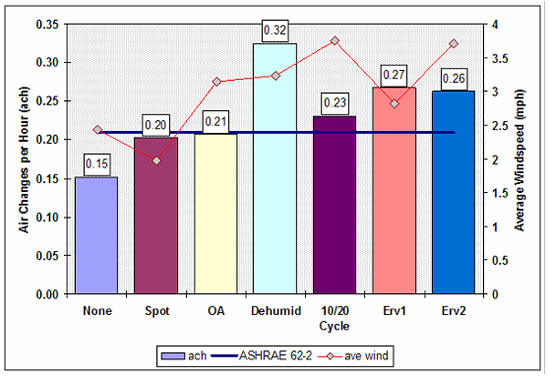

a tracer gas for a decay analysis (Figure 60)

to determine if each ventilation strategy met the ASHRAE

62-2 Ventilation Standard during the test period. The spot

ventilation strategy (#2) did not meet the standard on

a daily basis as the runtime was not long enough. The outside

air method (#3) was marginal in meeting the standard. Strategies

#4-#7 met the standard.

Figure 60 Results of tracer gas decay

testing indicating operational infiltration

(house not

under test pressure) rates measured for each ventilation

strategy.

ASHRAE Standard 62.2 was the target ventilation

rate, not met by Spot or OA

strategies. Note:

Wind speed averaged over 2 hour infiltration test.

Whole House and Duct Air Tightness: The average

whole house air leakage (CFM50) was 1224 (ACH50 of 5.4).

The target normalized duct leakage is Qn #6%, where Qn=CFM25/conditioned

area, this is the same as the duct leakage target in

the Manufactured Home Energy Star program. The total

duct system leakage in the MHLab Qn total=5% (CFM25 total

= 75) with leakage to the outside measured to be Qn (out)=3%

(CFM25 out = 45), well under the leakage target.

Interior temperature and relative humidity: A

digital thermostat maintained interior temperature at 75

degrees Fahrenheit. Interior temperature and relative humidity

sensors are located on the same wall as the thermostat,

at approximately the same height from the floor. Dedicated

interior relative humidity control was only available with

the dehumidifier strategy, and was a byproduct of cooling

coil operation in the other strategies.

Cooling/ventilation power usage

With all mechanical ventilation systems, additional energy

use from both increased conditioning loads and fan (if

present) power is expected. The split system with the floor

duct system is a 12 SEER system with a rated cooling capacity

of 30.2 kBtu. The ventilation strategies that required

the use of the air handler fan, an energy recovery ventilator,

or the dehumidifier had the energy use added to the cooling

energy. The dehumidifier strategy did use the most energy

for cooling; however, it should be noted that this test

occurred during the hottest ambient conditions.

Findings

The

cooling energy required to maintain the 75°F interior

set-point appeared to vary as a result of the temperature

difference across the envelope (Table 33). A linear

regression analysis was performed to compare energy use

of the ventilation strategies as a function of temperature

difference across the envelope (Table 34). The

power use at the average temperature difference of five

degrees Fahrenheit is shown in bold.

Table

33 Average Ambient and Building Conditions |

| . |

Case 1 None |

Case 2 Spot |

Case 3 OA |

Case 4 Dehumid |

Case 5 10/20 |

Case 6 ERV1 |

Case 6 ERV2 |

Case 7

Hstat |

Indoor

Temp (°F) |

74.5° |

74.5° |

74.7° |

74.9 ° |

74.0° |

74.1° |

74.4° |

74.8° |

Indoor

Temp Max (°F) |

75.0° |

75.2° |

75.5° |

76.0 ° |

75.0° |

74.9° |

75.4° |

76.0° |

Indoor RH (%) |

49.2% |

45.7% |

49.5% |

47.9% |

49.1% |

47.8% |

47.2% |

45.7% |

Indoor

Dewpoint (°F) |

52.4° |

54.2 |

54.5 |

53.9 |

53.7 |

53.1 |

53.0 |

52.4 |

Outside

Temp (°F) |

78.6° |

78.6° |

78.4° |

82.1 ° |

79.8° |

79.3° |

80.8° |

79.2° |

Outside RH (%) |

89.2% |

79.5% |

87.7% |

83.4% |

87.0% |

90.0% |

86.9% |

88.1% |

Δ Temp (°F) |

4.3° |

4.0° |

3.7° |

7.1 ° |

5.8° |

5.1° |

6.5 |

4.4 |

Δ Dewpoint

(°F) |

18.6° |

20.7° |

19.5° |

22.4 ° |

21.4° |

22.7° |

23.3° |

22.6° |

Solar Rad. (kWh/m

2) |

53.5 |

107.3 |

68.9 |

76.3 |

86.8 |

66.3 |

101.9° |

77.1° |

Rainfall (Inches) |

3.6 |

0.5 |

4.7 |

0.1 |

4.0 |

5.1 |

3.2 |

4.9 |

Condensate (lbs) |

617 |

905 |

920 |

1131 |

1118 |

1034 |

1685 |

1282 |

Δ P

WRT Out (Pa) |

-0.2 |

0 |

0.1 |

0.4 |

0 |

-0.2 |

-0.2 |

0.1 |

Minimum RH |

42.1% |

38.8% |

45.8% |

46.2 % |

46.3% |

44.2% |

39.3% |

39.7% |

Maximum RH |

53.3% |

55.2% |

53.2% |

51.0 % |

58.4% |

64.8% |

53.0% |

61.4% |

Mean RH |

46.1% |

49.2% |

49.5% |

47.9 % |

49.0% |

47.8% |

47.2% |

45.7% |

RH Standard Deviation |

1.272 |

1.471 |

1.673 |

0.845 |

1.231 |

2.194 |

2.108 |

3.07 |

RH Range |

11.2 % |

16.3 % |

7.4 % |

4.8 % |

12.1 % |

20.6 % |

13.7 % |

21.7 % |

- Case 4, the dehumidifier system, has the highest average

power at 1592 watts.

- Case 7 (humidistat controlled fan speed or Hstat) is

second highest at 1485 watts.

- Case 5 (10/20 cycle controller) used the least power

at 1315 watts.

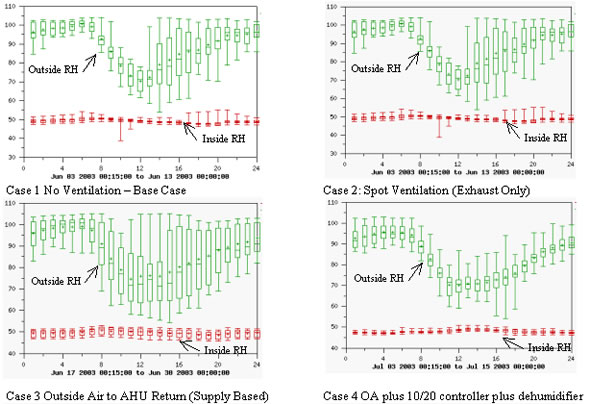

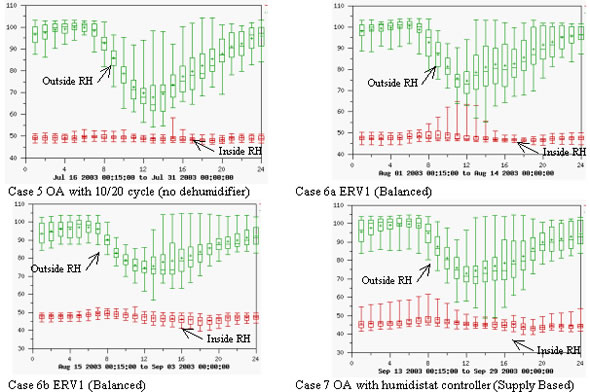

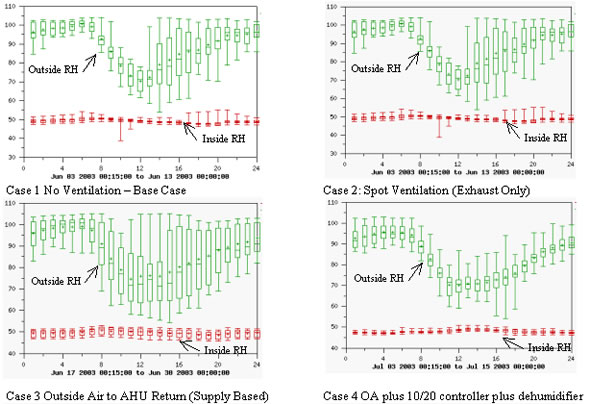

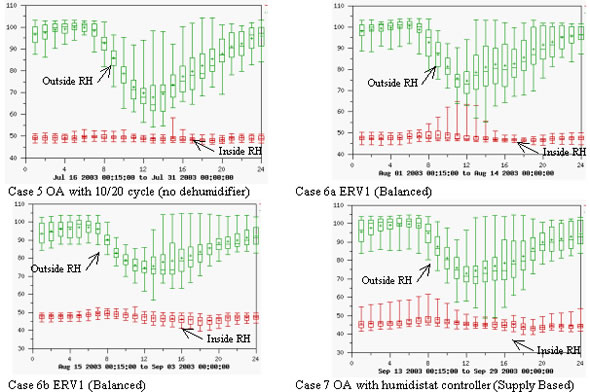

As might be expected, interior relative humidity had the

least variance with the dehumidification system with a

low of 46% and a high of 51% (Table 33 and Figure 61).

The best performing system, Case 4 (10/20 cycle plus dehumidifier),

was able to maintain the relative humidity at a nearly

constant level for almost 80% of the test period. The next

best performer was Case 2 (spot ventilation). Humidity

levels during the test period are graphed in Figure

61.

Table

34 Cooling and ventilation power (watts) usage as

a function of temperature difference across the building

envelope |

ΔTemp

(°F) |

Case

1 None |

Case

2 Spot |

Case

3 OA

|

Case

4 Dehumid |

Case

5 10/20 |

Case

6 |

Case

7 Hstat |

ERV1 |

ERV2 |

-5 |

487 |

499 |

475 |

499 |

411 |

459 |

367 |

526 |

0 |

924 |

911 |

949 |

1046 |

863 |

915 |

880 |

1006 |

5 |

1361 |

1324 |

1424 |

1592 |

1315 |

1370 |

1393 |

1485 |

15 |

2236 |

2150 |

2372 |

2685 |

2219 |

2280 |

2418 |

2443 |

Figure

61 Average hourly relative humidity

profiles for each strategy

Conclusions

The operation of a correctly sized air conditioning system

with a supplemental dehumidification system to pre-condition

the outside air and provide additional dehumidification

of the space appears to provide the best interior humidity

control (Table 33, in bold) with only a slight

increase in energy usage – about 200 watts (Table

34). This is represented by Case 4 of this study.

Only this strategy was able to maintain the interior humidity

conditions in a range of less than 5% (Table 34,

in italics).

Though

all of the strategies did provide some humidity control

over the test period, it is most likely a result of the

run time afforded by the correctly sized air conditioning

system and the consistent simulated interior sensible load.

When an air conditioning system operates for extended periods

of time, the removal of moisture from the air stream is

enhanced (Khattar, Swami & Ramanan 1987).

Additional testing with other ventilation strategies in

the MHLab will be undertaken in the next budget period.

- Manufactured

Housing Energy Use Study, North Carolina A&T

Paper: W. Mark McGinley, Alaina Jones, Carolyn

Turner, Subrato Chandra, David Beal, Danny Parker,

Neil Moyer, and Janet McIlvaine. Optimizing Manufactured

Housing Energy Use. Symposium on Improving Building

Systems in Hot and Humid Climates, Richardson, Texas,

May 17-19, 2004.

Side-by-side

monitoring of two manufactured homes at North Carolina

Agricultural and Technical State University (NCA&TSU),

evaluated the value of a variety of energy saving technologies

and techniques. (Figure

62 and Table 35) Home instrumentation measured

energy consumption as well as interior and exterior

climatic conditions. The “standard home,” designed

and built to basic HUD code requirements, represented

the control home. Modified to use at least 50% less

energy, the “energy home” met Building

America standards. Cooperating researchers at NCA&TSU

and FSEC investigated energy feature performance and

compared actual energy used to energy modeling program

predictions. In-situ energy performance data provided

researchers with interesting information on both issues.

Figure 62 Side-by-side

monitoring of manufactured homes at NCA&TSU.

Each

model contained 1,528 ft 2 of living area with nearly

identical floor plans. Though the homes were unoccupied

during the testing, home lighting and water heating use

was simulated with timers. A datalogger in each home

recorded: (1) the interior and exterior temperature and

humidity along with solar radiation and wind speed, (2)

the home’s total power

consumption, (3) the air conditioning/heat pump compressor,

air handler fan, and electric resistance heater use

(primary heater in the standard house, backup or

emergency heater for the energy house), and (4) water

heating and water usage data.

The energy house features combined higher insulation

values, improved windows, centralized and airtight

duct design, high efficiency heat pump, and a solar

water heater. Feature-by-feature construction differences

are highlighted in Table 35.

Table

35 Specifications of Standard and Energy Construction |

Characteristic |

Standard House |

Building America

House |

square footage |

1528 |

1528 |

floor insulation |

R-11 |

R-22 |

wall insulation |

R-11 |

R-13 |

ceiling insulation |

R-20 |

R-33 + roof deck

radiant barrier |

windows |

single pane with interior

storm |

low-E double pane |

exterior doors |

storm door on front |

storm door on all |

marriage wall seal |

fiberglass pad |

SOF-SEAL® gasket |

heating system |

resistance electric |

heat pump HSPF 7.5 |

cooling system |

central air conditioning

SEER10 |

central heat pump

SEER12 |

system size |

3 tons |

2 tons |

water heating |

electric

water heater – 40

gallon |

solar

water heater – 66

gallon |

duct joints |

industry standard |

sealed with mastic |

duct leakage |

*CFM5out = 145 |

CFM25out = 83 |

house leakage |

**ACH50 = 10 |

ACH50 = 9 |

*Cubic

feet per minute **Air changes per hour |

Data collection on the two

homes began in early January 2001 and continued through

this reporting period. Palm Harbor Homes in Siler City

manufactured both homes, the results for program year three

and four are detailed below.

Year 4 Side-by-Side Monitoring Results

During

Phase 2, modifications were made to the solar water heating

system in the energy efficient housing unit to help improve

the performance this system. Further, a number of the

incandescent light bulbs in the energy unit were replaced

with compact fluorescent bulbs. These changes were staged

to allow an evaluation of the effect of each measure

on the home’s energy use.

Based on investigative results, it can be concluded that:

- Changes

in the building envelope, HVAC and duct systems, and

fenestrations in the energy home met researchers’ 50%

energy use reduction goal. Measured annual energy savings

for heating and cooling energy was 58%, and 53% for heating,

cooling, and hot water production.

- Care

should be exercised in the manufactured housing unit

setup or relatively minor construction deficiencies

can significantly reduce a home’s energy efficiency.

Many of these items are invisible to the homeowner; therefore

procedures must be developed to ensure that deficiencies

do not occur during setup.

- The Energy Gauge energy analysis program appears to

give a reasonably accurate prediction for expected energy

use reduction in a typical manufactured housing configuration.

The predicted energy savings for the housing units evaluated

in this investigation ranged from 54% to 63%, while the

measured values ranged from 53% to 58%. Version 2.0 of

the Energy Gauge Program provided a more accurate energy

savings prediction than the older software versions.

- An increase in pipe and tank insulation can increase

not only the energy efficiency of a solar water heater

by reducing stand-by losses, but also can reduce the

cooling load in a manufactured housing unit and increase

the overall energy efficiency of the water heating unit.

Even small amounts of exposed piping can significantly

affect the energy efficiency of the water heating system.

- While providing essentially the same lighting levels,

replacing incandescent lamps with compact fluorescent

bulbs not only reduces lighting energy use, but also

reduces the home cooling load.

The total measured energy used by each of the housing

units for cooling and heating are shown in tables below. Table

36 shows the energy used for heating and cooling the

standard housing unit from January through August of 2002.

The standard home datalogger was struck by lighting in

mid-August 2002. Data after this point was not included

since only partial data is available and performance comparisons

were not possible. Table 37 shows a summary of

the cooling and heating energy used by the energy housing

unit. Tables 38 and 39 list the energy use for

hot water production for the standard and energy units,

respectively.

Table

36 Cooling and Heating Energy Use, Standard House Actual

Values (kWh ) |

| . |

SEP |

OCT |

NOV |

DEC |

JAN |

FEB |

MAR |

APR |

MAY |

JUN |

JUL |

AUG |

Phase

1 |

492.4 |

447.6 |

648.6 |

1741.1 |

2495.3 |

849.6 |

628.8 |

384 |

566.3 |

990.8 |

852.9 |

1066 |

Phase

2 |

. |

. |

. |

. |

2120.2 |

1717.1 |

1227.6 |

502.0 |

438.0 |

939.4 |

1079.4 |

511.2 |

|

Table

37 Cooling and Heating Energy Use, Energy Star

House |

. |

SEP |

OCT |

NOV |

DEC |

JAN |

FEB |

MAR |

APR |

MAY |

JUN |

JUL |

AUG |

Phase

1 |

337.3 |

205.7 |

150.8 |

452.8 |

1087.3 |

472.8 |

426.9 |

184.8 |

528.3 |

891.5 |

850.9 |

671.6 |

Phase

2 |

. |

. |

. |

. |

680.7 |

537.1 |

378.1 |

241.9 |

311.8 |

603.0 |

668 |

626.6 |

|

Table

38 Domestic Hot Water Use, Standard House |

. |

SEP |

OCT |

NOV |

DEC |

JAN |

FEB |

MAR |

APR |

MAY |

JUN |

JUL |

AUG |

Phase

1 |

197.8 |

267.7 |

250.2 |

212.6 |

0 |

0 |

217.6 |

244.9 |

258.1 |

227.5 |

207.9 |

213.5 |

Phase

2 |

. |

. |

. |

. |

294.6 |

280.9 |

283.2 |

264.9 |

280.2 |

192.2 |

200.3 |

85.2 |

|

Table

39 Domestic Hot Water Use, Energy Star House |

. |

SEP |

OCT |

NOV |

DEC |

JAN |

FEB |

MAR |

APR |

MAY |

JUN |

JUL |

AUG |

Phase

1 |

133.4 |

176.2 |

204.2 |

189.9 |

0 |

0 |

245.5 |

184.4 |

183.0 |

141.2 |

152.3 |

126.6 |

Phase

2 |

. |

. |

. |

. |

251.1 |

212.0 |

202.8 |

145.9 |

157.3 |

74.8 |

80.3 |

83.0 |

Also listed in each table are the monthly energy use

values measured during the first phase of this investigation,

January through August 2001. Please note that the energy

housing unit data prior to August 2001 is suspect due to

duct and HVAC system problems later corrected. The entire

data set, including, temperature, relative humidity, solar

radiation, and power use is listed on the FSEC web site

www.infomonitors.com .

The total energy used for water heating and central cooling

over the period of August 1 through August 15 was 363.5

kWh for the energy home and 596 kWh for the standard home.

This represents a 40 % reduction in energy use between

the two homes.

The total energy used over the period of August 1 through

August 15 for water heating was 27.13 kWh for the energy

house and 85.18 kWh for the standard home. This represents

a 68% reduction in energy use with the solar water heating

system and compares well with the June and July reductions

of 63% and 60%, respectively. Consistent findings indicate

that the tank and piping insulation has reduced the standby

tank losses and improved the solar water system efficiency.

In the energy housing unit, three of the 100 watt incandescent

lamps that were on the evening four-hour timed duration

were exchanged for 25 watt compact fluorescent lamps on

June 4th. This change did appear to have a small effect

on the cooling load in the energy housing unit. The relative

cooling energy used by each of the housing units from June,

2002 through August 2002 showed a small change. The percentage

reduction in cooling energy used by the energy housing

unit increased from about 30% to 38%. However, it is difficult

to isolate the effects of the improvements in the solar

water heating system insulation and the effects of the

compact fluorescent bulbs. In any event, these effects

appear to be much smaller than that produced by the hot

water system changes.

Year 3 Side-by-Side Monitoring Results :

|

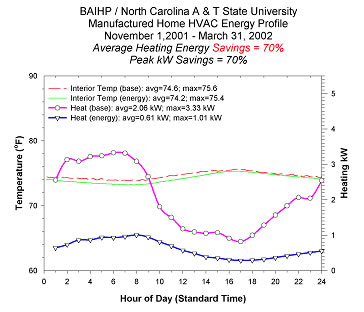

Figure

63 Heating

season consumption and savings for side by side study

of Energy Star Manufactured Housing. |

Heating

system savings (2001 to 2002) were a remarkable 70% during

Phase 1. Cooling energy season savings were 36%, less than

heating but still very substantial. The combined heating,

cooling, and water heating savings were 52% for a 9-month

period. (Figure 63)

In

addition to the energy monitoring effort, NCA&TSU

researchers investigated the feasibility of replacing the

conventional framing/envelope used in manufactured/industrial

housing with alternative systems. Included in this evaluation,

was an analysis of the energy impact of using aerated autoclaved

concrete (AAC) flooring systems and structural insulated

panels (SIP) to supplant traditional wall and roofing systems.

The economic viability of using AAC blocks for structural

skirting/foundation around the model units also was evaluated.

Analysis’ results

determined:

- The best manufactured home energy performance can

be achieved using the SIP wall and roof systems with

the AAC plank. This performance can be further enhanced

with an R-8 unvented crawl space. Though a manufactured

home performs best with these alternative systems, the

cost to include them may not make economic sense.

- AAC planks can be designed to replace both the steel

frame and flooring systems for HUD code manufactured

housing units and modular units. These planks also can

be modified to incorporate built-in insulated ducts.

- AAC planks are pre-manufactured and require less assembly

labor than a typical stick framed unit, but including

the plank flooring would increase framing costs by 28%.

The heavier weight of an AAC system might exacerbate

high framing costs. Similarly, comparative analysis results

found that replacing a conventional framing system with

a SIP system would increase framing costs by 66%.

- At the current prices for energy and wood products,

neither the AAC plank system nor the SIP systems are

as economically effective as improvements in the current

conventional HVAC systems, steel and wood framing, sheathing

systems, and air barriers with respect to improving energy

performance.

- The use of AAC planks has the potential to be economically

viable in the modular housing market, especially if used

with sealed crawl space foundation systems, where their

improved resistance to moisture degradation would be

very important.

- SIP wall and roof systems also could prove to be economically

viable if the price of wood energy increases, and the

SIP manufacturing costs decrease through large volume

purchases.

- The

proposed AAC planking system presents a system that

is significantly less affected by water and moisture

degradation and may be effective in reducing manufactured

housing units’ susceptibility to flood damage.

These systems also are not susceptible to termite attack.

- The

savings from reduced transportation damage from greater

durability and increased floor system stiffness were

not addressed in this investigation. It wouldn’t

take many days of damage repair (at about $300/person-day

for personnel costs related to transportation) to vastly

improve the economics of these alternative systems.

|