|

BAIHP

Research: A. Manufactured Housing Research Cont'd

- Building Science and Moisture Problems

in Manufactured Housing

Papers: Subrato Chandra, Danny Parker, David Beal, David

Chasar, Eric Martin, Janet McIlvaine, Neil Moyer. Alleviating

Moisture Problems in Hot, Humid Climate Housing. Position

Paper for NSF Housing Research Agenda Workshop, UCF Feb.

12-14, 2004.

Moyer,

N., Beal, D., Chasar, D., McIlvaine, J., Withers, C, & Chandra, S. (2001). “Moisture Problems in

Manufactured Housing: Probable Causes and Cures.” ASHRAE

- IAQ 2001 Conference Proceedings, San Francisco, CA.

|

Figure 45 Palm

Harbor HUD Code Manufactured Housing factory – production

line. |

|

Figure

46 Completed

HUD Code Manufactured Home, Palm Harbor Homes. |

Manufactured

homes have a permanent steel chassis attached below the floor

and are constructed in a factory (Figure 45) to

meet a national code maintained by the U.S. Department of

Housing and Urban Development (HUD). After production, homes

may travel a few hundred miles, hauled by truck, before final

setup. The homes are setup by placing blocks under the steel

I-beams and anchoring the beams firmly to the ground. A skirting

covers the blocks and steel frame in a fully setup home (Figure

46).

Manufactured

homes are typically heated or cooled by a system of ductwork,

which delivers hot or cold air from the air handler unit

(AHU). The ductwork can be in the attic or in the belly cavity

of the home. The ducts are typically made of aluminum or

fiberglass trunk lines which supply air to the floor registers

through in-line boots or flex ducts. The boots or ducts terminate

at perimeter registers on the floor. Supply duct leaks represent

one of the biggest causes of moisture problems in manufactured

homes. (Figures 47 and 48). Poor design and construction

leave holes at the AHU connection to the main trunk, and

where the boots connect to the trunk, supply registers, end

caps, cross-over duct connections, and other connection points.

When the AHU blows air, some air leaks into the belly and

eventually to the outside through belly board tears. This

loss of air creates a negative pressure inside the house

and a positive pressure in the belly. The negative pressure

pulls outside or attic air into the house through cracks

and crevices which connect the inside of the house to the

outside or to the attic. During northern winters, this outside

air is cold and dry and its entry increases occupant discomfort

and heating energy use.

|

| Figure

47 Pressure field and unintentional

air flow created by supply duct leaks. |

During

summer in the Southeastern US, the air is consistently at

or above the dewpoint of 75. If a homeowner keeps their home

thermostat set below this 75 F dewpoint, the moisture laden

outside air condenses as it comes into contact with the cold

inside surfaces. If it condenses behind an impermeable surface

such as vinyl flooring or wallpaper, serious mold, mildew,

and floor buckling problems can result.

Many manufactured and site-built homes have only a single

return and, therefore, very little return air transfer from

the bedrooms (basically via the undercut at the bottom of

interior doors). When interior doors are closed, rooms off

the main body (e.g., bedrooms) become pressurized and the

main body of the house depressurizes. Even though negative

pressures are usually only one to three pascals (Pa) - they

can cause serious problems in a home.

Researchers

use a calibrated fan called a ductblaster to measure duct

leakage. The ductblaster is attached to the return grill

or the crossover duct opening (Figure 49) and

all supply registers are masked off and the fan is turned

on. Once the house ductwork reaches –25 Pa, airflow

through the fan is read (in CFM). The resultant measure

is the total duct leakage. In good airtight ductwork, total

duct leakage (CFM@25 Pa) should be less than 6% of the

homes square footage.

|

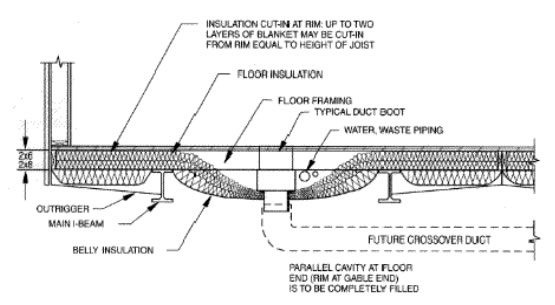

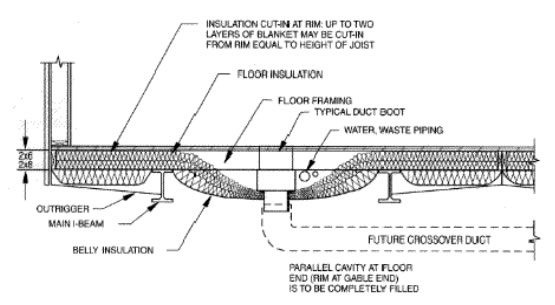

| Figure 48 Cross section

showing foundation support, crossover duct, and one

type of ventilation system in a manufactured home. |

A

second duct leakage test measures leakage to the outside.

This leakage is calculated by depressurizing the entire

house to –25 Pa with a blower

door, then adjusting the ductblaster flow so there is no pressure difference

between the house and the ducts. This measurement is a true indicator of

duct air loss to the outside and is used in energy calculations for estimating

the energy loss from leaky ducts. In good duct systems, duct leakage to

the outside (in CFM) is less than 3% of the home’s

square footage.

|

| Figure 49 Floor and

belly area with supply ducts. These ducts supply conditioned

air to all rooms through floor vents, a common duct

system layout in manufactured homes. |

The battery of tests run

in a problem house typically includes measuring

the airtightness of the house with a blower door,

depressurizing the house to –50 Pa. At

that time, the house to belly and belly to crawlspace

pressures also can be measured. Researchers also

test pressure differentials caused by AHU operation

and closed interior doors. An additional measurement

of duct leakage, called pressure pan, is conducted

on some houses to pinpoint specific registers which might

have large leaks. In this measurement the house is first

depressurized to –50 Pa and all the register vents

are unmasked. Then the registers are covered one by one

and the pressure difference between the covered register

and the house is measured. A zero reading indicates no

leakage at that register. Readings over one Pa indicate

a sizeable leak that should be repaired.

- BAIHP

Field Visits to Moisture Problem Homes

Papers:

Moyer, N., Beal, D., Chasar, D., McIlvaine, J., Withers,

C, & Chandra, S. (2001). “Moisture

Problems in Manufactured Housing: Probable Causes and

Cures.” ASHRAE - IAQ 2001 Conference Proceedings,

San Francisco, CA.

A significant number of new manufactured houses built

to HUD code and located in the hot, humid Southeast have

exhibited moisture problems. Soft wallboards, buckled

floors, damaged wood molding, and extensive mold growth

are the most common symptoms. These problems do not respond

to the standard service and repair strategies for water

intrusion. (Please see Appendix B for sample problem

home inspection trip reports.)

Summary of 1 st-4 th Budget Period Field Visits to

Moisture Problem Homes

At

the request of six manufacturers, 69 such moisture damaged

homes were investigated from 1999 to the end of reporting

year four (through March 31, 2003) to determine likely

causes. In Year 4 alone, 18 homes were investigated by

FSEC. One-time blower door, duct tightness, and pressure

differential measurements were performed on all homes.

Field data on ambient, crawlspace, belly and house temperatures,

plus relative humidity levels were collected on a few of

the homes. Recommendations and reports were prepared for

the manufacturers’ service, production, and

design staff. Field repairs were performed in most

of these homes. A general theme was found in the houses

investigated.

- Air conditioner thermostat settings (typically 68

to73 F) set below the ambient dew point.

- Negative

pressures across the envelope from high supply duct leakage

(CFM @25Pa >10

per 100 square feet of conditioned floor

area), inadequate return air paths, interior

door closures, exhaust fans, or a combination

thereof.

- Inadequate moisture removal from disconnected return

ducts, continuous fan operation (air handler

or ventilation), inadequate condensate drainage, oversized

air conditioners, or a combination thereof.

- Moisture diffusion from the ground into the house

because of poor site drainage, inadequate

crawl space ventilation, tears in the belly board, or a

combination thereof.

- Vapor-retardant in the wrong location (i.e., vinyl

or other impermeable wall or floor coverings

located on the colder surfaces).

Recommended solutions provided to the manufacturers

to eliminate moisture problems included:

- Maintain air conditioning thermostat settings above

the ambient dew point (at least 75 F).

- Eliminate long-term negative pressures created by

air handler fans or ventilation equipment.

- Tightly seal all ductwork and provide adequate return

air pathways.

- Enhance moisture removal from the conditioned space

by correct equipment sizing and maintenance.

- Eliminate ground source water and provide an adequate

moisture barrier for the floor assembly.

- If possible, remove vapor barriers located on the

wrong surfaces.

Research continues to determine if these steps will

be sufficient to prevent problems even when vapor barriers

are incorrectly located in homes in the hot, humid climate.

Preliminary results are encouraging. One manufacturer

has not reported a single new moisture problem in any

of the homes produced since 2000 in a factory that previously

had a significant number of problem homes. Steps taken

by the factory were inclusion of airtight duct systems

(a zero net-cost increase), right-sized cooling systems

(a negative cost), return air ducts from all bedrooms

(a cost of about $15), installation of a ground vapor

barrier (no change from previous practice).

Summary of 5 th Budget Period Field Visits to Moisture

Problem Homes

|

Figure

52 HUD Code

required perforations in skirting may not allow adequate

volumes of ventilation, creating higher than usual

vapor pressure difference across the floor assembly

even though the ground cover and belly board are in

good condition. |

BAIHP researchers at FSEC received fewer requests in the

5 th budget period for assistance with moisture damaged homes (Table

27), reflecting improvement of duct construction and

sealing, addition of return air pathways from bedrooms, and

reduction of vapor impermeable interior surfaces. Additionally,

service personnel who have attended BAIHP training and participated

in field work with BAIHP are more prepared to resolve problems

without assistance. Service personnel report installing passive

return air vents in bedrooms, providing appropriate moisture

barriers, and sealing duct leaks to resolve humidity, comfort,

and moisture damage call backs.

When service personnel have been unable to resolve a problem,

they request assistance from BAIHP researchers who attend

a service call and conduct various diagnostic tests to identify

factors contributing to the moisture, comfort, or high energy

bill problem. (MHRA has been providing similar services on

a fee basis to the industry also.) After BAIHP researchers

complete a field visit, a trip report is issued detailing

the findings and recommendations, include basic building

science background material.

Table

27 5th Budget Period – FSEC Field Visits

to Problem Manufactured Homes

|

Manufacturer |

Location |

Date |

Fleetwood Homes |

Florida (2 homes) |

August 03 |

| . |

Florida (2) |

November 03 |

| . |

Texas (1) |

December 03 |

| . |

West Virginia (1) |

March04 |

Cavalier Homes |

Florida (1) |

November 03 |

Southern Energy Homes |

Kentucky(1) |

December 03 |

| . |

Texas (1) |

January 04 |

Style Crest |

Louisiana (1) |

February 03 |

20 NEEM Program Manufacturers |

Field Visits in Washington, Oregon,

and Idaho (19) |

April 03-March 04 |

Total Homes |

29 |

. |

It

has been BAIHP’s experience that corrective measures

from repeated moisture problem Diagnostics have been incorporated

into the production process, resulting in thousands of improved

manufactured homes. These are noted in Category D of

Table 2.

A common problem that remains unresolved involves the combination

of abundant crawl space moisture (Figure 50 and 51) and

poorly vented skirting (Figure 53). In the hot-humid

coastal regions, this combination raises vapor pressure across

the belly to critical levels. This was evident in several

of the homes visited this year. As a result of this field

research, BAIHP has designed a study that will be initiated

in the summer of 2004 to evaluate the moisture flow characteristics

of crawl space conditions.

Northwest BAIHP Random Home Testing

SGC Random Home Testing: In 1994-1995 (prior

to implementation of BAIHP), SGC staff conducted field testing

of 178 SGC homes built in 1992-1993. In 1999, the first year

of the BAIHP effort, staff in Idaho and Washington field-tested

49 SGC homes built in 1997-98. In 2000, analysis of field

test data confirmed some improvements to home set-up procedures

and air leakage control, while highlighting a need to improve

duct tightness and ventilation system operation (through

homeowner education.) In 2001, BAIHP staff produced an updated

homeowner ventilation brochure.

In 2002 and 2003, BAIHP staff worked with Ecotope to develop

a valid sample for the next round of field testing, and began

to develop the field testing protocol. In 2004, Ecotope selected

105 homes from the total production for the years 2001-2002.

The field testing took place in the summer of 2004. Findings

from the testing include:

- Average house size is 1769 ft 2; double section homes

are also getting bigger, on average. The house size is

very comparable to the homes built in 1997-1998 but 20%

larger than the homes in 1994-1995 study

- Houses are getting tighter, according to the blower

door results. The average air leakage rate at 50 Pa is

4.2, which represents a tightening of almost 25% over the

original MAP home average. The median equivalent leakage

area (ELA) for double-section homes has decreased by about

12% despite a substantial increase in house size.

- Only about 20% of NEEM homes in this study contain intentional

outside air inlets. This is the result of BAIHP research

indicating that intentional outside air inlets are unnecessary

to provide adequate fresh air.

- 2/3 of homes in the study have dedicated whole house

fans and a substantial fraction of homeowners are using

their whole house fans. However, a significant minority

(30%) does not turn them on.

- About half of homes in the study use central cooling,

with more than half of these homes using a heat pump.

- Duct systems are about 20% leakier than in the Year

1 study and about 10% leakier than in the 1994-1995 study

(when the comparison is normalized by house size).

- The median supply leakage fraction is 11-13% for the

homes in this sample. The duct loss translates into a heating

system efficiency loss of between 10-20% overall, depending

on the location of the home (west side or east side of

the mountains) and type of heating equipment (heat pumps

perform worse).

In 2004, BAIHP staff conducted a billing analysis on a

limited number of random field study homes. The conclusions

(although not statistically significant) suggest that temperature

related energy use in NEEM homes remains similar to previous

larger studies on cost-effectiveness. The analysis attempted

to evaluate total and space conditioning energy use by HVAC

system types but was limited by small sample size.

In

2004, a sub-sample of homes that are believed to represent

the best case for duct tightness were selected for additional

field testing. These homes include those with in-plant tested

ducts and thru-rim crossover duct systems. The goal of this

effort is to establish a “tightest” duct case

benchmark. Field testing will be completed in 2005; report

will follow.

Northwest BAIHP Field Visits to Problem Manufactured

Homes

|

Figure

51 The downstream

exit for the water draining across the site via the

crawl space. Note flow pattern away from house. |

|

Figure

52 HUD Code

required perforations in skirting may not allow adequate

volumes of ventilation, creating higher than usual

vapor pressure difference across the floor assembly

even though the ground cover and belly board are in

good condition. |

In

offering technical support to owners of over 100,000 homes

built since 1990, the BAIHP staff in the Northwest answers

questions from homeowners, manufacturers, retailers and

others. In The 6th budget period, staff from Washington,

Oregon and Idaho responded to over 70 phone calls and conducted

27 field visits. The number of field visits to problem

homes has significantly decreased over the history of the

program, in large part because of manufacturers’ and installers’ increased

adoption of the NEEM Super Good Cents/Energy Star (SGC/E-Star)

specifications which include duct air tightness specifications

(duct leakage is a major contributor to pressure and air

flow related moisture problems), and the requirement that

manufactured home installers be certified in Washington and

Oregon.

Northwest BAIHP staff began to utilize Energy Gauge USA

as a toll for evaluating high bill complaints in 2003-2004.

BAIHP staff participated in quarterly meetings of the Washington

State Manufactured Housing Technical Working Group, which

coordinates the certification of manufactured housing set-up

crews.

While butyl duct tape is no longer allowed under current

NEEM SGC/E-Star specifications, a consistent issue in the

field continues to be excessive duct leakage, due in large

part to failures of duct tape. These findings were brought

to the attention of the NFPA-501 Manufactured Housing Standards

Committee, resulting in a successful proposal to revise the

duct sealing specifications to eliminate the use of duct

tape in favor of better performing mastic and fiberglass

mesh in the NFPA-501 standard. See a summary of supporting

research findings in BAIHP Duct Data Compilation.

Blue Sky Foundation

Blue Sky Foundation, in coordination with FSEC, conducted

an evaluation of energy efficiency and the moisture damage

potential in 16 North Carolina homes in the summer of 2001.

Blue Sky foundation proposed that the energy and moisture

evaluation focus on the building envelope integrity, HVAC

duct systems, and the moisture impact of unvented space heaters.

All of the homes in the study were manufactured models located

in Carteret and Craven counties, each located on the North

Carolina coast. Field teams gathered additional energy and

moisture information from homeowners.

Only three of the 15 tested homes recorded moisture and/or

mildew problems. Because of the small sample size, the results

are mostly anecdotal and would need to be evaluated within

a larger data set. Planning for this is underway. Data from

the summer field program as well as the final report are

now on the BAIHP website (www.baihp.org)

under Publications.

Cavalier Homes

BAIHP visited one Cavalier Home in Florida for a moisture

damage investigation in response to home owner complaints

of persistent air flow problems and floor damage. BAIHP made

recommendations to correct the installation of the duct system

and supply registers, repair the rodent barrier to make it

air tight, do site work to reduce flooding under house, place

a ground cover if site work done, increase crawl space venting,

and replace damaged flooring with plywood.

Figure 53 Testing Results

from Fleetwood Homes Plant in Alma, Georgia

illustrate

that tape sealed ducts can result in total duct leakage

under

Qn=<6%.

This initial tightness, however, is often eroded by adhesive

failure.

Fleetwood Homes

During

the 5 th budget period, BAIHP continued to support Fleetwood’s

service department making six visits to moisture damaged

homes in Florida (4), Texas (1), and West Virginia (1).

Six Fleetwood homes, all in Florida, were tested for moisture

and mold damage from April 2002 through March 2003, the 4

th budget period. All of the homes had damaged flooring due

in part to a lack of ground cover and poor crawlspace ventilation.

Damage to the floor in one home was exacerbated by a plumbing

leak. Only one home had moisture damage to the wallboard

material, and this home showed a history of thermostat settings

below 72 F. A report for each home was submitted to Fleetwood

for corrective measures. One additional high bill complaint

in Cobb, Georgia was investigated during this reporting period.

In 2002, four Fleetwood factories in Southern Georgia were

visited to investigate possible causes of moisture related

building failures found in homes installed in hot, humid

climates. The factories were located in Douglas, Alma, Pearson,

and Willacootche. (Figure 53.)

Homes of Merit

In

2002, researchers performed multiple diagnostic tests on

a home located in Marathon, Florida that was experiencing “mold

problems.” Researchers determined that the mechanical

system was significantly oversized and that the home was

operating under negative pressure when the system was operational.

The home’s owner exacerbated humidity problems by leaving

the fan in the “on” mode. On-site relative humidity

readings showed that indoor and outdoor relative humidity

were the same, approximately 70%.

|

Figure 54 Wall assembly used

in moisture transmission experiment. |

Palm Harbor Homes

(See also, Palm Harbor Homes in Section I, Technical

Support and Manufactured Housing Indoor Air Quality Study

in Section III, Research, below).

Palm

Harbor Homes, James Hardie®, and

FSEC performed two separate drywall assembly tests to determine

the cause of some moisture damage occurring in homes sheathed

with Hardipanel. Hobo dataloggers recorded temperature

and relative humidity measurements inside the assembled

panels on eight different wall panel configurations. (Figure 54.)

Results determined that the unprimed, unwrapped sheathing

performed best. The painted drywall assemblies allowed the

greatest moisture movement - or wall assembly drying. (Table

28) The vinyl-covered drywall held moisture longest,

recording the slowest drying time. Adding perforations to

the vinyl reduced the drying time.

Table

28 Hardipanel exterior wall configurations |

Test Panel |

Drywall |

Insulation |

Wall Wrap |

Sheathing |

#1 |

vinyl |

unfaced |

none |

primed |

#2 |

vinyl |

unfaced |

none |

unprimed |

#3 |

vinyl |

unfaced |

house wrap |

primed |

#4 |

perforated vinyl |

unfaced |

none |

primed |

#5 |

House wrap glued to

drywall |

unfaced |

house wrap |

primed |

#6 |

vinyl |

unfaced |

Thermo Ply |

primed |

#7 |

painted |

unfaced |

none |

primed |

#8 |

painted |

unfaced |

none |

unprimed |

In 2002, two Palm Harbor homes with comfort problems were

tested in Ocala and Okahumpka, Florida and one high bill

complaint was investigated in Odessa, Florida. Duct leakage

testing and infrared imaging revealed a duct disconnect near

the attic crossover in the Ocala home. Inspections with the

IR camera found no insulation problems in the Odessa home.

Ductblaster and blower door tests revealed airtight duct

and envelope systems. Other than an oversized air conditioning

system, there were no obvious reasons for the high bills.

Southern Energy Homes

(See also, Southern Energy Homes in Section I, Technical

Assistance.)

During Year 2001, 12 homes were field tested in the Houma,

Louisiana area. Some of the homes had new moisture damage.

Others were rechecks of previous moisture problems already

repaired by SEH personnel. FSEC inspectors reported improper

repairs and recommended additional dealer and staff training.

An additional five homes were field tested in Houma during

the 4th reporting period, with another home in Mississippi

and one in Alabama also field tested.

During the 5 th budget period, BAIHP visited two Southern

Energy Homes in Texas (1) and Kentucky (1).

-

Side

By Side Study Of Energy Use And Moisture Control

Comparing Standard Split System Air Conditioning

And A Coleman® Prototype Heat

Pump, Bousier City, LA

Research led BAIHP Researchers Dave Chasar, Neil

Moyer, and Chuck Whithers

Papers:

Withers, C., Chasar, D., Moyer, N., and Chandra, S. "Performance and Impact from Duct

Repair and Ventilation Modifications of Two Newly Constructed

Manufactured Houses Located in a Hot and Humid Climate",

Thirteenth Symposium on Improving Building Systems

in Hot and Humid Climates, May 20-22, 2002 Houston,

Texas.

In

2001, the BAIHP team conducted research on two homes to

define how tight ducts and a prototype Coleman® heat

pump (proprietary technology) affect energy use and moisture

control in a hot, humid climate. FSEC, in collaboration

with Fleetwood Homes, York International Manufactured

Housing Division (now Stylecrest Sales), and Coleman®,

monitored two nearly identical side-by-side homes in

Bossier City, Louisiana. The homes contained different

air conditioning systems. House A used a standard split

air conditioner, while House B used the Coleman® prototype

unit (a more efficient, two-speed split air conditioner).

Figure 55 Power draw over

a 24-hour period, September 2, 2000.

Figure 55 shows the reduced power draw of the two-speed

compressor (green, dotted line) over a 24-hour period on

September 2, 2000. With the unit operating at low-speed for

most of the day, the cooling energy savings were 28% when

compared to the energy use in House A. Average daily cooling

energy was reduced by about 12% over the monitored period.

An added benefit of the two-speed air conditioner was 20%

greater moisture removal on days with an outdoor dewpoint

above 60 F.

Savings from Duct Repair and POS Ventilation: In addition

to comparing one house to the other, the BAIHP team also

compared home performance before and after ductwork and ventilation

system changes were made.

To make the comparison, duct and other leaks were sealed

in both houses until the two were equally airtight. The ventilation

method in each home also was changed from exhaust-only to

a positive pressure system (POS). With exhaust-only ventilation,

bathroom fans removed stale air from the home which caused

fresh air to be pulled in through the building envelope.

To simulate occupant use, two bath exhaust fans were operated

by a timer for three hours in the morning and six hours in

the evening.

In contrast to exhaust ventilation, the POS system introduced

a small amount of fresh air on the return side of the air

conditioning cooling coil. A POS system was installed in

each home at the same time the ducts were repaired. Subsequent

monitoring looked at the effects of this alternate ventilation

system. Tightening the ducts and installing a POS ventilation

system resulted in an 18% and 37% cooling savings in the

two homes. Only about 2% of these savings were attributable

to the ventilation system change, the remaining savings are

a result of duct repair.

- WSU

Energy House

Olympia, Washington

Technical Assistance by BAIHP Contractors Washington

State University Energy Program, Oregon Office of Energy

and Idaho Department of Water Resources, Energy Division

|

Figure

56 WSU Energy

House in Olympia, WA |

This

2600 ft 2 home was built beyond SGC standards and incorporates

Energy Star lighting and appliances. The home (Figure

56) has received significant national exposure through

WSU campus and alumni newsletters, tours, the BAIHP website,

and local and trade media including an article in the

Automated Builder magazine and a feature by KING 5 News

of Seattle.

WSU staff uses the house to try out innovative technologies

and testing methods.

In

2003, BAIHP staff developed a moisture case study based

on research at the WSU Energy House, published under a

separate Building America project. The WSU Energy House

has been monitored since 2000. Collected

monitoring data includes weather, temperature, humidity,

CO 2, CO, and eight differential pressures. Energy

use data is being collected for water heating, laundry,

fireplace and heating, ventilating, and air conditioning

(HVAC). Data from the house is available on the

BAIHP web page (under Current Data) and has been presented

to the building science, indoor air quality (IAQ) and

HVAC research communities at conferences sponsored by

ASHRAE, Air Infiltration and Ventilation Center (in the

UK), HUD/NIST, NFPA, and BTECC. (See

also Appendix D, WSU)

Working

with Ecotope, ASHRAE, and the Energy Conservancy, BAIHP

staff conducted “Delta Q” and “nulling” duct

leakage tests in 2001. Follow up pressure tests

and analysis of test data conducted in 2002 indicate

these tests are effective methods of measuring duct leakage

in manufactured homes, and may be included in the upgrades

to the National Fire Protection Association-501 standards

for manufactured homes.

Blower door and duct leakage testing indicate very good

whole house and duct airtightness (2.4 ACH50 and 61.6

CFM50 out). Tracer gas testing demonstrated that the

use of a furnace-based intake damper does not change

the leakage rate of the home.

In 2004, moisture problems associated with siding and

trim details were eliminated using and an improved window

flashing system. The adoption of this system is currently

under discussion with some manufacturers, and NFPA-501.

|

You

are here: >

You

are here: >