|

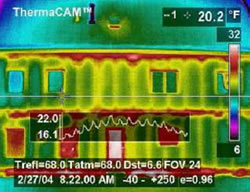

Figure 11 Completed Dukane

Precast home tested by BAIHP |

FSEC

made a February 2002 site visit to Dukane Precast in Naperville,

Illinois and provided technical design assistance in a

follow-up telephone conference call in March ‘02.

In

2003, Dukane Precast requested BAIHP assistance in the

design phase and monitoring of the first prototype of a

new line of homes called “The Fortified House (Figure

11). Objectives of Dukane’s Fortified House include

energy efficiency, comfort, durability, and good indoor environment

conditions.

In December 2003, FSEC visited 3 prototype buildings in

various stages of construction in. One was complete. Researchers

made recommendations regarding window flashing, below grade

drainage and waterproofing, interior ducts, air sealing,

attic access detail, floor finishes with radiant heating,

radiant heat zoning, ventilation system design and operation.

In

February, FSEC returned to Dukane for testing and infrared

evaluation of 3 completed prototype Fortified Homes built

by Dukane’s sister company,

Mustang Construction at Keller Court, Boilingbrook, IL,

just west of Chicago.

Infrared

images were recorded from the inside and outside during

a calm morning with ambient air temperature of about 25 º F and interior temperatures of about 70 º F,

and whole house air tightness was assessed with a blower

door test. Whole house infiltration was ACH50=1.28 (very

low) 11 Keller Court data (Specifications, Table 11) was

obtained with a multipoint blower door test. IR scans found

no major infiltration pathways.

The ceiling and gable end of the vaulted living room were

built with wood frame construction instead of precast concrete.

Both showed higher heat loss than was generally found in

the precast panels. Flaws in the continuity of ceiling insulation

over the vaulted ceiling were visible from the vented attic.

especially around can lights. The flat ceilings in this home

were insulated with R-38 rigid polyisocyanurate loosely laid

on the concrete ceiling panels. Dukane has now switched to

an R-23 precast panel for ceilings.

Table

11 Dukane Precast’s Fortified Home Specifications |

Component |

Dukane Home |

Conditioned area |

5100 (with basement) |

HERS score |

NA |

Envelope |

Floors and Ceiling |

Precast concrete panels |

Walls |

R-23

(~3") Polyisocyanurate

between precast concrete |

Attic |

Vented with R-38 Polyisocyanurate and

Batt |

Windows |

Insulated glass, vinyl frame, u-value=0.36,

SHGC=0.45 |

Infiltration |

Ach50=1.28 |

Equipment |

Heating |

Radiant floor |

Boiler |

140kBtu, 50 gallon AFUE=92 Gas Boiler |

Cooling |

3 ton, 10 SEER, Unico-type |

Ducts |

High velocity, small ducts, unconditioned

space |

Thermostat |

Programmable |

Ventilation |

Honeywell 150cfm HRV |

Water Heating |

From Boiler |

Opportunities

for Improvement

|

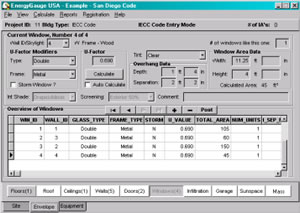

Figure

12 IR-scan

showing metal trusses

in precast walls. Temperature at the crosshairs is 20.2 ° F. Overlaid

temperature graph shows temperature variation of

the surfaces at the white line running horizontally through the crosshairs. |

Infrared scans were performed on the ranch home and two

other homes nearing completion on Keller Court. All three

had the space heating system in operation holding the interior

near 70 F. Initial scans of the exterior clearly showed increased

heat conduction at the truss locations in the precast panels (Figure

12). The metal truss members are cast into the assembly

to connect the interior and exterior panels and allow for

approximately 3 inches of polyisocyanurate foam (R-23). Exterior

infrared scans showed a 2 - 4º F temperature rise at

truss locations; exterior temperatures were between 12º and

24ºF.

Increased heat loss was also visible at the top and bottom

of precast sections where field connections are made during

construction and filled with grout. Each panel has at least

two lifting fasteners imbedded in the top edge for the crane

to connect to during home construction. Foam insulation around

these fasteners is sometimes removed to connect the lifting

hook and the void is re-insulated in the field. Insulation

levels are reduced where precast walls are connected to floors

and ceilings. These areas have one inch of rigid XPS foam

(R-5) next to the outer panel but are otherwise left open

until structural and electrical conduit connections are made

in the field after which they are filled with grout.

Interior Ducts and Moisture Issues

FSEC Researchers met with Dukane Precast staff, their architect

and mechanical contractor to identify a way to incorporate

interior ducts into a new model of the Fortified House. Ducts

are used primarily for cooling and ventilation as all Dukane

Precast homes are designed with in-floor radiant heat driven

by a high efficiency (92 AFUE) boiler. The boiler also provides

domestic hot water in conjunction with a 50-gallon storage

tank.

The main obstacle to building interior ducts was finding

a place to run ducts from the basement mechanical room to

the first and second floors. Agreement was made to run supply

risers near the center of the home and returns in a chase

on an outside. The two-story foyer offers the best placement

for a central return for both the first and second floor

supplies.

Dukane

is currently using a high velocity, small duct air conditioning

system by Unico with 2-inch diameter supply branches that

are easier to fit into walls and chases than low velocity

ducts. One unoccupied home had problems with condensation

accumulating on the attic-mounted ducts. The cause was

traced to humid indoor air contacting cold metal trunk

lines in the vented attic.

No occupant-related moisture was present but the precast

panels, which are still in the process of drying, are one

possible source. Periodic mixing of the indoor air may be

all that is required until moisture output from the panel

is reduced. Otherwise, introducing dry air was recommended

to prevent condensation. Findings and recommendations were

sent of the Dukane Precast in a Trip Report.

- Dye Company and DelAir - Southern Living Home

Florida H.E.R.O. met with Dye Company president

and his staff to discuss the new Southern Living Home planned

for showcase at the 2003 Southeast Building Conference

(SEBC) in Orlando, Florida. This firm has a strong desire

to differentiate their homes by emphasizing healthy and

energy efficient homes. Florida HERO introduced the Building

America systems engineering approach to the builder and

subsequent discussions resulted in Dye’s commitment

to partner with Building America in this project. As a

result, researcher met with DelAir mechanical contracting

to discuss the development of mechanical specifications

for the Southern Living project.

This home did have a Honeywell ERV added and had a HERS

score of 88.5. While this home did not meet the BA standard

of performance for the 2003 SEBC show, retrofits are being

completed with the anticipation that it will be a BA home.

The 2004 home achieved a HERS of 89.6. Both homes have unvented

attics with ducts in conditioned space, and used heat pumps

with SEERs ranging from 13.5 - 14.1. Windows in the 2004 home

have a SHGC of .29 and gas (LP) instant hot water heaters were

used.

|

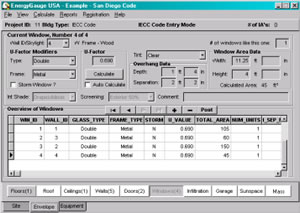

Figure

13 Window input

screen from EnergyGauge USA home energy rating

and

simulation software |

This software uses the hourly DOE 2.1E engine with FSEC

enhancements and a FSEC-designed user friendly front end

to calculate home energy ratings and energy performance. (Figure

13) Researchers continue to improve the software’s

features and accuracy. Version 2.0 incorporates many enhancements,

which may include multiple zones, multi-fuel use, and a detailed

solar thermal and solar electric system analysis. For more

information, please visit www.energygauge.com.

In 2002, researchers visited four Fleetwood factories in

southern Georgia to investigate the cause of moisture-related

building failures when units were installed in a hot-humid

climate. The factories are located in Douglas, Alma, Pearson,

and Willacootche. As a result of FSEC recommendations, the

factories have changed their duct construction practices

and are now constructing airtight ducts with mastic.

Six

Fleetwood homes, all in Florida, were tested for moisture

and mold damage from April 2002 through March 2003. All

of the homes had damaged flooring due in part to a lack

of ground cover and poor crawlspace ventilation. Damage

to the floor in one home was exacerbated by a plumbing

leak. Only one home had moisture damage to the wallboard

material, and this home showed a history of thermostat

settings below 72° F.

A report for each home was submitted to Fleetwood for corrective

measures. One additional high bill complaint in Cobb, Georgia

was investigated during that period. Between April 2003 and

March 2004 eight Fleetwood moisture damaged homes were investigated

by BAIHP, seven in Florida and one in Texas.

In May 2003, FSEC researchers were asked by Fleetwood and

Coleman to travel to Fleetwood's five southeastern plants

and test three homes built by each factory to get their plants

certified for building EnergyStar Homes. A sample of the

data collected is shown in Table 12.

Table

12 Test Results, Factory Certification at Fleetwood’s

Auburndale facility |

House

# |

Size |

ACH50 |

Estimated

natural ach (ACH50/18) |

Qn

total

(CFM25

total/ cond. area)

|

1 |

24 X 48 |

8.7 |

0.48 |

0.031 |

2 |

28 X 52 |

5.5 |

0.31 |

0.034 |

3 |

28 X 52 |

5.5 |

0.31 |

0.029 |

At the Auburndale, FL plant, BAIHP researchers conducted

the tests in houses set up in the factory's parking lot.

The houses did not have air handlers, but total duct leakage

was within range to achieve Fleetwood's goal for this plant

which was to build houses according to the EPA EnergyStar

Building Option Packages (BOPs) for manufactured housing,

Climate Zone 4, and to attain a less than 5% duct leakage

rate (Qn,total #5%). The houses showed some need for additional

envelope sealing which was implemented after the first house

was tested. The other two houses showed marked improvement

in whole house air tightness. Recommendations and test results

were provided to Fleetwood via email (no formal trip report).

Similar testing was conducted at the Georgia Fleetwood factories

in Willacoochee, Pearson, Douglas, and Alma.

|

You

are here:

You

are here: