APPENDIX

B

UCF

HOUSING CONSTRUCTABILITY LAB - ANNUAL REPORT

Progress

Report: April 2003-March 2004. Prepared for: The Industrialized

Housing Partnership & The Building America Program. Sponsored

by: U.S. Department of Energy. Prepared by: UCF Housing

Constructability Lab, Dr. Michael A. Mullens, PE. Date:

June 15, 2004.

UCF researchers continue to identify and develop prototype

applications of computer technology for the modular factory

floor. Research efforts this year focused on real time production

labor data collection. While labor represents a relatively

modest fraction of production cost, typically 10-15%, it

has a profound impact on operations, including product quality,

cycle time, material waste, and labor productivity. The Status

Tracking and Control System (STACS) is a real time shop floor

labor data collection and reporting system. Production workers

use wireless laser scanners to report their current work

assignment. STACS reporting is web based and provides both

real time manufacturing status and summaries of historical

production performance.

An alpha prototype of STACS was tested in drywall finishing

operations at Avis American Homes (Avis, PA) in Summer 2003.

Test results demonstrated that production workers could operate

the system effectively and that the system accurately captured

scanned activity. Large scale plant-wide testing began at

Penn Lyon Homes (Selinsgrove, PA) in March 2004 and will

continue into Summer 2004. Test results will be used to develop

labor models using linear regression and neural nets.

Trinity Construction Corporation is a large shell contractor

serving Florida homebuilders. Faced with increasing demands

for higher quality, lower cost and more timely delivery,

Trinity is actively exploring innovative alternatives to

conventional concrete block construction, the predominant

homebuilding technology in the central and south Florida

market. Trinity operates a pre-cast concrete panel production

facility, in South Bay, Florida where concrete panels are

pre-cast , transported to the construction site, and quickly

assembled using a construction crane. The UCF Housing Constructability

Lab (HCL) was asked to assist Trinity in improving the current

panelizing process by incorporating lean production principles.

Preliminary research determined that material

handling and rework were primary contributors to the 47%

of labor consumed by non-value added activities. Once started,

the flow of value-added activity was routinely interrupted.

Poor access to materials and tools, rework, ill-defined process

flows, and workforce/1 st line supervision issues were contributing

factors. To address these issues, HCL researchers utilized

lean production principles - challenging non-value added

activities and removing the obstacles to continuous production

flow. Recommendations addressed issues of organization/communication,

structured procedures and work flow, material handling, and

off-line sub-assembly.

To

test the recommendations, Trinity allowed HCL researchers

to perform a 3-day pilot test. The test involved a single

house consisting of 25 wall panels with a gross wall area

of 3,119 ft 2. Productivity increased for all observed

activities, with an average increase of 68%. Not all recommendations

could be realized during the test. Some equipment and personnel

issues could not be resolved on a short-term test basis.

This suggests that the true potential is significantly

greater than that observed during the test – possibly

approaching 200% increase in labor productivity. Corresponding

cycle time reductions are estimated to be 20-25%. This

successful pilot test has given Trinity the opportunity

to develop a competitive advantage in the housing construction

market and a good foundation to dominate it.

- Innovative Applications of Computer Technology

on the Factory Floor

UCF

researchers continue to identify and develop prototype

applications of computer technology for the modular factory

floor. Research efforts this year focused on the collection

of real time production labor data. While labor represents

a relatively modest fraction of production cost, typically

10-15%, it has a profound impact on operations. Except

for the slower winter months, experienced labor is a scarce

resource. Even if labor is sufficient in the aggregate,

it is rarely positioned where it is most needed at a particular

moment in time. Competitive market pressures are resulting

in an increasing mix of custom home features, increasing

the likelihood of “floating bottlenecks” in

production. Quality and safety can suffer as undermanned

crews rush to complete custom features (i.e., fire-rated

walls or a hip roof). If a crew cannot keep pace, the line

slows, production rate drops, overtime is required and

delivery dates are missed. In

the past, the sheer number of production activities, lengthy

cycle times and extensive product customization have

discouraged manufacturers from accurately estimating labor

needs and using this information to plan and control production.

Instead, they have responded by controlling labor at

the overall plant level, attempting to maintain labor at

a historical target value, which is stated as a percentage

of overall production cost or sales revenue. A limitation

of this approach is that it seldom reflects the actual

labor content in the product, particularly in periods of

increasing customization. To address the problem of shifting

bottlenecks, many manufacturers use flexible resources

termed “utility workers”, “flex

workers”, or expeditors. However, the decision to

deploy these workers is often made with minimal planning,

after a problem has started to impact the line. To

better understand the true usage of production labor, the

UCF research team has developed the Status Tracking and

Control System (STACS). STACS is a real time labor data

collection and reporting system designed specifically to

meet the needs of the industrialized housing industry.

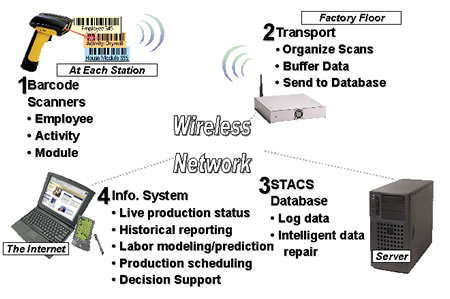

A schematic of the STACS system is shown in Figure 1. Production

workers use wireless laser scanners to report their current

work assignment. Scanned information is transmitted immediately

to a base station and then relayed to a local shop floor

processor, where it is verified and temporarily staged.

Information is periodically transmitted via wireless LAN

to a central database server where it is stored and used

for reporting. STACS reporting is web based and provides

both real time manufacturing status and summaries of historical

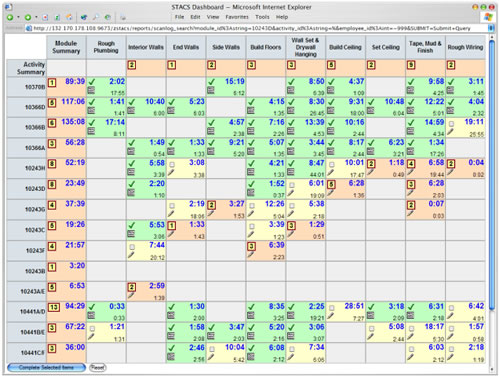

production performance. Real time production performance

can be monitored from the web-based STACS Dashboard (Figure

2). “Clicking” on

any item on the Dashboard will display corresponding real-time

details. Historical results can be used for a variety of

analytical and management purposes:

- The development of analytical labor estimating models.

These models can be used to estimate labor requirements

for product costing, production scheduling and labor planning.

- As a baseline for continuous improvement efforts.

An alpha prototype of STACS was tested in drywall finishing

operations at Avis American Homes (Avis, PA) in Summer 2003.

Test results demonstrated that production workers could operate

the system effectively and that the system accurately captured

scanned activity (Figure 3). Large scale plant-wide testing

began at Penn Lyon Homes (Selinsgrove, PA) in March 2004 and

will continue into Summer 2004. Test results will be used to

develop labor models using linear regression and neural nets.

|

| Figure

1 Structure of STACS system |

|

| Figure

2 STACS real-time dashboard |

|

| Figure

4 Scanning drywall activities at Avis America |

-

Lean Production of Precast Concrete Panels

Trinity Construction Corporation is a large shell contractor

serving Florida homebuilders. Faced with increasing demands

for higher quality, lower cost and more timely delivery,

Trinity is actively exploring innovative alternatives to

conventional concrete block construction, the predominant

homebuilding technology in the central and south Florida

market. Trinity operates a pre-cast concrete panel production

facility, in South Bay, Florida where concrete panels are

pre-cast (Figure 1), transported to the construction site,

and quickly assembled using a construction crane (Figure

2). The UCF Housing Constructability Lab (HCL) was asked

to assist Trinity in improving the current panelizing process

by incorporating lean production principles.

|

|

Figure

1 Panel forms

on forming bed |

Figure

2 Setting pre-cast

concrete

wall panel |

Preliminary research involved extensive observation

and analysis. Value stream mapping identified activities

that contributed value to the customer as well as activities

that added little or no value. Material handling and rework

were primary contributors to the 47% of labor consumed by

non-value added activities. Once started, the flow of value-added

activity was routinely interrupted. Poor access to materials

and tools, rework, ill-defined process flows, and workforce/1

st line supervision issues were contributing factors. To

address these issues, HCL researchers utilized lean production

principles - challenging non-value added activities and removing

the obstacles to continuous production flow. Recommendations

addressed issues of organization/communication, structured

procedures and work flow, material handling, and off-line

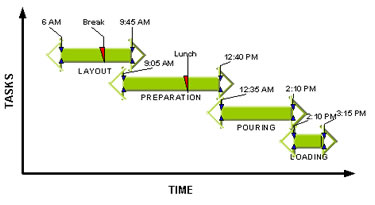

sub-assembly. A typical recommended daily production flow

is shown in Figure 3.

|

Figure

3 Summary of typical daily

production schedule using continuous

flow |

To

test the recommendations, Trinity allowed HCL researchers

to perform a 3-day pilot test. The test involved a single

house consisting of 25 panels. The panels had a total of

21 window and door openings and a gross wall area of 3,119

ft 2. The first day was spent organizing and training the

test production team and the second and third days were

dedicated to production. All 25 panels were produced. Productivity

increased (Table 1) for all observed activities. Lifting

productivity was not observed. Conservatively assuming that

lifting will remain at historical levels, overall labor productivity

increased by 47%. If lifting productivity is assumed to increase

at the average rate observed for the other activities, overall

productivity would increase 68%. Not all recommendations

could be realized during the test. Some equipment and personnel

issues could not be resolved on a short-term test basis.

This suggests that the true potential (Table 1) is significantly

greater than that observed during the test – possibly

approaching 200% increase in labor productivity. Corresponding

cycle time reductions are estimated to be 20-25%.

Table 1.

Productivity - ft 2 of wall/ labor hour |

Process

Phase

|

Existing

Process

|

Potential

Process Results

|

Pilot

Test Results

|

Productivity

Increase

during Test

|

Layout |

53 |

152 |

91 |

72% |

Prep |

52 |

149 |

79 |

52% |

Pouring |

146 |

211 |

296 |

103% |

Lifting |

75 |

440 |

75* |

0% |

Total |

17 |

49 |

25 |

47% |

The

HCL research team recommended that Trinity proceed with

implementation of the lean production recommendations.

In addition to the technical recommendations, the research

team also made recommendations involving worker empowerment,

dealing with the heat and sun, and material/equipment availability. Potential

future research areas include covers for the production

area, on-site factories in new home developments, and factory

installed wall insulation. This successful pilot test has

given Trinity the opportunity to develop a competitive

advantage in the housing construction market and a good

foundation to dominate it.

-

Publications and Presentations

Mullens,

M. and M. Kelley, “Lean Homebuilding

Using Modular Technology,” Housing and Society: Journal

of the Housing Education and Research Association. In

Press

Mullens,

M. and M. Hastak, “Defining

a National Housing Research Agenda: Construction Management

and Production” Proceedings

of the NSF Housing Research Agenda Workshop, Feb. 12-14,

2004, Orlando, FL. Eds. Syal, M., Mullens, M. and Hastak,

M. Vol 2.

Mullens,

M. “Production flow and shop

floor control: Structuring the modular factory for custom

homebuilding” Proceedings

of the NSF Housing Research Agenda Workshop, Feb. 12-14,

2004, Orlando, FL. Eds. Syal, M., Mullens, M. and Hastak,

M. Vol 2.

Mullens,

M. and I. Nahmens, “Lean

Principles Applied to Pre-cast Concrete Homebuilding,” Industrial

Engineering Research ‘04 Conference Proceedings,

Houston, May, 2004.

Elshennawy,

A., M. Mullens, I. Nahmens, “Quality-Based

Compensation Schemes for Modular Homebuilding,” Industrial

Engineering Research ‘04 Conference Proceedings,

Houston, May, 2004.

Nahmens,

I., M. Mullens and A. Elshennawy, “The

Impact of Demographics on New Homebuyer Satisfaction,” Industrial

Engineering Research ‘04 Conference Proceedings,

Houston, May, 2004.

Broadway,

R. and M. Mullens, “Shop

Floor Information Systems for Industrialized Housing Production,” Industrial

Engineering Research ‘04 Conference Proceedings,

Houston, May, 2004.

|

You

are here:

You

are here: