- Building America Prototype, Cambridge Homes

|

Figure 56 The Augusta, Cambridge

Homes

Building America Prototype. |

The

partnership between BAIHP and production builder Cambridge

Homes began late in 2001. Cambridge Homes had recently

signed on with the EPA Energy Star Homes Program as a 100%

Energy Star builder and expressed interest in increasing

energy efficiency even further, as well as adding some “healthy

home” features to their product. Also, Cambridge Homes

expressed interest in BAIHP helping them design and build

in a way that would prevent moisture related problems and

call backs.

BAIHP began by conducting analysis on several typical home

designs and presenting results and strategies in a number

of meetings with the builder. BAIHP also arranged a special

meeting with the American Lung Association of Central Florida

to discuss achieving the ALA Health House designation on

the showcase model. However, the builder decided not to pursue

the health house designation at that time.

To

implement Building America strategies outlined by FSEC

researchers, Cambridge Homes constructed a “prototype

house” (Figure 56) to ensure that the strategies

mate well with their current building practices (Table

33). A variety of home plans were reviewed to select

an appropriate demonstration home, as well as a standard-practice

counterpart. During construction, both homes were outfitted

with dataloggers and associated monitoring equipment.

The

homes were built in Baldwin Park, a new Orlando subdivision

being developed on land that was once home to the Orlando

Naval Training Center. The development will be 30% larger

than New York’s Central Park,

totaling approximately 1100 acres. Four hundred acres have

been set aside for parks and open space, while 700 acres

will be used for the construction of 3,000 homes, one million

square feet of office space, and 200,000 square feet of

retail space. Cambridge Homes is one of ten builders constructing

homes in the community and plans to build 700 homes in

Baldwin Park over the next five years.

Table

33 Cambridge Homes Specifications |

Component |

Base Case (Covington) |

Prototype (Augusta) |

Conditioned Area |

2446 ft2 |

2672 ft2 |

Envelope |

Above-Grade Wall Structure |

CMU first floor

2X4 Frame second floor

|

Same |

Above-Grade Wall Insulation |

R-3.5 rigid foam

R-13 Fiberglass Batt

|

R-3.5 rigid foam

R-13

|

Above-Grade Wall Sheathing |

OSB |

Same |

Attic |

Vented r-30 batt |

Unvented r-19 Icynene |

Roof |

Owens corning shingle |

Elk architectural shingle |

Windows |

Single pane, clear

Metal frame

|

Double pane, low-e

Metal frame

|

Infiltration (ACH50) |

Not tested by FSEC |

3.0 |

Equipment |

# Of Systems |

2 |

1 |

Heating |

Heat pump HSPF = 8.65 |

Same |

Cooling |

2.5 ton, 13 SEER

2 ton, 13 SEER

|

5 ton, 13 SEER |

Thermostat |

Programmable

Standard

|

Programmable |

Ventilation |

None |

Thermastor Ultra-Aire |

Water Heater |

50gallon Electric EF 0.88 |

Same |

Lighting |

10% fluorescent |

100% fluorescent |

Appliances |

Standard |

Energy Star |

Hers Score |

87 |

87.6 |

The demonstration home gave the builder firsthand experience

with unfamiliar design elements, some of which have been

incorporated into their standard practices. Such unfamiliar

design elements included vapor permeable wall insulation,

low-e windows, whole house dehumidifiers, unvented attics,

and compact fluorescent lighting. FSEC researchers closely

monitored the construction of the prototype and standard

practice home, which was built to the Energy Star level.

A duct test was performed in the prototype house during mechanical

rough in to ensure leakage specs were met. Meetings also

were held with the builder's HVAC contractor to discuss installation

of the whole-house high efficiency dehumidification, filtration,

and ventilation unit in the prototype model.

Upon completion of the home, duct testing was repeated to

include inspection of the whole house dehumidification unit,

and infrared camera analysis was conducted on the home. Data

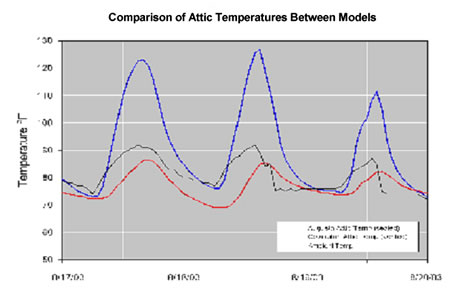

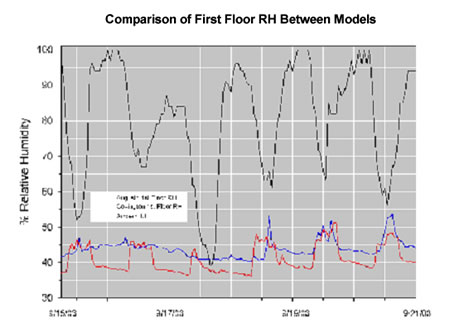

(Figures 57 and 58) collected from the two homes

showed marked improvement in attic temperature (a primary

cooling load) and indoor relative humidity control.

BAIHP

performed training for Cambridge Homes' sales staff in

March 2003. The training took place within the completed “prototype” model.

Training focused on the advanced features of the Building

America showcase model which Cambridge Homes began offering

in April 2003.

|

Figure 57 Comparison

of attic temperatures between

Cambridge Homes BA

Prototype (Augusta) and Standard Cambridge Homes

construction (Covington). Graph shows how sealed

attic construction in Augusta results in lower attic

temperatures than

vented attic construction during

cooling season in Orlando, FL. |

|

Figure 58 BA Prototype

(Augusta) contains whole house

dehumidification system.

Plot shows daily cycling of the

system resulting in

a lower relative humidity in the prototype

home than

in the standard Cambridge Homes construction. |

Late

in 2003, Cambridge Homes began construction of a second

home similar to the “prototype” model,

which was purchased by a customer impressed with its attributes.

FSEC staff conducted training for builder and sales staff

in December 2003 to review design methodologies and lessons

learned from the prototype model. A second meeting was held

in January 2004 inspect progress of the home. Upon moving

into the home, Cambridge Homes reports that the new homeowner

is extremely happy with the home.

To

assist Cambridge Homes with reducing callbacks and moisture

reduction problems, FSEC researchers have also conducted “total” and

to “out” duct tests on six other Cambridge homes

to determine why the total duct leakage numbers were high

(>10% of fan flow) despite low to “out” duct

leakage. “Out” is defined as outside the conditioned

space, including buffer spaces like an attic or garage. Consistent

leakage was found around the boot to register grill connections.

FSEC worked with Cambridge Homes and their HVAC contractor,

DEL-AIR, to specify air tight register grills.

- Unvented Attic Study, Rey Homes

Rey

Homes, a production builder in Orlando, in 2001 pledged

to build a community of 200 homes that meet both Energy

Star standards (HERS = 86) and the Florida Green Home Designation

Standard. Rey’s partnership with FSEC

began in October 2001 when researchers analyzed Rey’s

standard home designs and construction and made recommendations

for complying with these standards.

In the fourth budget period, Rey built 2 homes in their

Villa Sol community for side by side comparison of unvented

attic construction, a BAIHP recommended strategy. FSEC installed

monitoring equipment in both homes, one with an unvented

attic and one with a standard vented attic including a set

of moisture pins in each house to monitor the moisture content

of roof trusses in addition to the usual complement of temperature,

humidity, and energy use meters. Instrumentation was complete

early in the fifth budget period; however, data collection

was not successful due to equipment and site complications.

- Sharpless

Construction, Hoak Residence Energy and Moisture Studies

|

Figure 59

Hoak residence

in Longwood, Florida . |

This three-story, 4,250 square foot home was completed in

February 2001 by Mr. David Hoak and Sharpless Construction

in Longwood, Florida near Orlando. (Figure 59) FSEC

assisted the owner and builder by recommending a package

of features that produced an exceptionally energy efficient

design at a reasonable cost. Because the building envelope

design and mechanical equipment selection work together as

a system, the home can be cooled with a much smaller air

conditioner than is needed by most homes of this size in

this climate.

Envelope Features:

High Performance Windows

Roughly

25% of the annual cooling load in a typical Central Florida

home is introduced through the windows. Recent advances

in window technology allow this load to be greatly reduced.

The windows in this residence are particularly useful in

Florida because they have a very low Solar Heat Gain Coefficient

(SHGC) to reduce direct solar gains, and a relatively high

Visible Transmittance (VT) for natural daylighting.

|

Figure 60

Semi-conditioned

space for the ductwork. |

Unvented Attic

Most Florida homes have vented attics with batt or blown

insulation applied just above the ceiling. This exposes

the air conditioning ductwork to very high temperatures

and magnifies duct leakage problems. Sealing the attic

envelope and insulating at the roof deck, as shown in Figure

60, provided a semi-conditioned space for the ductwork.

This reduced conductive heat gain and minimized the detrimental

impact of duct leakage.

Expanding Foam Insulation

A layer of expanding foam insulation

(Figure 60) was

applied to the underside of the roof deck to create an unvented,

semi-conditioned attic (R-22). The same insulation was applied

to all above-grade walls (R-11). While the insulation R-values

were standard, the foam created a nearly airtight seal and

greatly reduced outside air infiltration.

Continuous Air Barrier

|

Figure 61 Heat

pump water heater. |

Infiltration

of Florida’s hot and humid

outside air can have a big impact on energy use, building

durability, and occupant health. The continuous air barrier,

placed toward the outside of the building envelope, reduces

this infiltration. Indoor air quality concerns were addressed

by installing an energy recovery ventilator to introduce

outside air.

The

air barrier consists of a tightly taped housewrap installed

over the exterior sheathing on all above-grade frame

walls, and extruded polyurethane foam boards glued to

the interior of the below-grade block walls. Expanding

foam insulation provided an extra measure of airtightness

at all above-grade exterior surfaces including the roof

deck. Special care was taken to seal

wall details such as corners, floor interfaces, and the

roof junction. Blower door performance tests verified the

home’s

level of airtightness (ACH50 = 2.0).

Equipment Features: 2-Speed, Zoned Heat Pump

The

building envelope design features described above greatly

reduced the required air conditioner size. Manual-J HVAC

equipment-sizing calculations showed the need for only

2½ tons

of heating and cooling capacity. In this case the owner opted

for a two-speed compressor, which provides either 2½ or

5 tons of cooling or heating depending on the need.

The

Hoak home air conditioning unit typically operated in

the 2½-ton mode until the late afternoon

when it switched to the 5-ton mode for a few brief periods.

In this home, energy use stays low because the low compressor

speed operates the majority of the time. But, when quick

cool-down or excessive loads require more capacity, the

high speed compressor can meet the need.

Measured

data indicated that the 5-ton mode operated about one

in every four days during the three hottest summer months

(June to August), usually for periods of 15 minutes or

less. Even these short periods of high-speed compressor

operation might have been avoided with proper use of

a programmable thermostat. These results verify the Manual

J sizing calculations and indicate that if a single speed

HVAC system were installed, the optimum size would be

2½ to

3 tons.

Variable-speed Air Handler

Two benefits of using a variable-speed motor for air distribution

are better moisture removal and energy efficiency. During

the cooling season, slower airflow across a cold coil allows

for more moisture removal. Wintertime comfort also is enhanced

with this operation, since the coil has more time to warm

before the air is brought to full flow.

Indoor

relative humidity tends to increase during the fall and

winter months when air conditioning activity declines.

Without a dedicated dehumidifier, the air conditioner is

the only means of reducing indoor relative humidity.

When there is a call for cooling - the low-speed compressor

in a variable speed system operates more consistently

than a larger system and keeps relative humidity from rising

to unhealthy levels.

Heat Pump Water Heater

Solar water heating would have been the first choice for

this home, but poor orientation and too many shade trees

forced a search for other options. (Figure 59) Natural

gas also was unavailable in the area. To avoid the inefficiency

of electric resistance water heating, a 6,000 BTU/hour heat

pump water heater ( Figure 61 ). Heat pump water

heater produced all the hot water needs for a four-person

household from April to September .

The

water heater was connected to a standard 80-gallon electric

water heater. By locating the heat pump inside the home,

homeowners gained a summertime benefit of additional

cooling and year ‘round dehumidification

because the system removes moisture each time it operates.

Energy Recovery Ventilator

The energy recovery ventilator acts as a conduit to flush

out stale indoor air and replace it with outdoor air. As

the indoor air is expelled, a heat exchanger recovers up

to 80% of the energy used to heat or cool the air and transfers

it to the incoming air stream. This unit also transfers a

portion of the moisture between the airstreams, which is

useful during periods of high outdoor humidity.

Airtight Ducts

Attic

and duct heat gain contribute to about 22% of the cooling

needs of a typical Central Florida home when are ducts

located in a vented attic above the insulation. While some

home efficiency is lost by direct heat-gain through the

duct insulation, a great deal more efficiency can be lost

from unintended duct leakage from the ductwork into the

vented attic. Duct leakage test results showed only 50

CFM of air was lost at 25 Pa of pressure differential in

the Hoak residence. This leakage equates to 1.2% leakage

per square foot of conditioned floor area - far below the

leakage normally found in new Florida homes.

Energy

Monitoring:

Monitors on the Hoak residence include 11 attic temperature

and relative humidity sensors, three indoor sensors, a Hobo

event logger to record the dehumidifier cycling time, and

a tipping bucket rain gauge with Hobo logger to monitor the

combined condensate of the air conditioner, dehumidifier,

and heat pump water heater. In 2002, Alten Design also assembled

a new logger monitoring computer with the capability of reading

data from two Campbell 21X loggers. This computer was configured

with remote monitoring and control capacity so that Partners

can program and maintain the system without traveling to

the site.

Findings

Duct Leakage

Duct

leakage test results showed the Hoak home air loss was

only 50 CFM at 25 Pa or 1.2% leakage per square foot

of conditioned floor area – far

below the amount of leakage normally found in new Florida

homes.

Total

duct leakage is less than 10% of air handler flow (200

CFM). Blower door performance tests verified the home’s

level of airtightness at two air changes per hour at 50

Pa (ACH50 = 2.0). When including leakage around the supply

grills, house leakage increased about 30%. Slightly more

than half of the house leakage (1479 CFM at 50 Pa) is located

in the sealed attic space (760 CFM at 50 Pa).

Cooling Energy

Initial data comparisons were made against data collected

from a Lakeland, Florida residence (PVRes), designed by FSEC

and monitored for more than a year. The PVRes home contained

the most energy-efficient provisions researchers could devise,

including a 5 kW photovoltaic system. Data collected at the

Hoak home shows the cooling energy is nearly on par with

the PVRes Home on a per square foot basis.

Envelope

Weekly data logs of the Hoak home provided by Alten Design

from the 14 Hobo temperature and relative humidity sensors

and pressure tests through March 2003, confirm that air pathways

between the unvented attic and outdoors still exist. Researchers

suspect that these pathways may be the primary source of

moisture intrusion into the unvented attic space. Several

whole house pressure tests (smoke tests) were performed by

Alten Design and FSEC to isolate these external sources of

air infiltration. Identified leaks were sealed, though actions

have shown some benefit moisture levels are still higher

than desired.

In order to isolate areas of leakage, barriers will be placed

in the house splitting the areas under test into easier to

monitor individual zones.

|

You

are here:

You

are here: