| Click here for PDF Version

Abstract

Four occupied homes near Dallas, Texas were monitored to compare

cooling energy use. Two homes were built with typical wood

frame construction, the other two with insulated concrete

form (ICF) construction. Remote data loggers collected hourly

readings of indoor and outdoor temperature, relative humidity,

furnace runtime fraction, total building electrical energy

and HVAC energy use. Data was recorded from January through

August 2000.

Analysis of the measured data shows that insulated concrete

form (ICF) construction can reduce seasonal cooling energy

use 17 - 19% over frame construction in two-story homes in

the North Texas climate. This result includes adjustments

to compensate for differences in miscellaneous energy use,

(e.g. lights & appliances), and duct leakage. While each

home pair had the same floor plan, elevations and orientation

there were some differences that were not accounted for in

the measured results. These included occupant impacts, exterior

wall color (absorptance) and the absence of an attic radiant

barrier in one ICF home.

In

addition to analyzing the measured data, two sets of DOE2

simulations were performed. An initial comparison of ICF and

frame homes modeled in their as-built condition was followed

by a comparison of homes modeled with identical features except

for wall construction. Both analyses showed a 13% annual cooling

energy savings for ICF over frame construction. This result

is comparable to a similar simulation study (Gajda 2001) of

a two-story home in the Dallas climate, which saved 15% annually

on both heating and cooling.

Introduction

Four

Centex homes near Dallas, Texas were monitored by the Florida

Solar Energy Center as part of the Building America Industrialized

Housing Partnership (BAIHP). Centex Homes and the Portland

Cement Association are two BAIHP partners that were involved

with the study. Two home models (Figure 1) were constructed

twice; one with typical wood frame construction and the other

using insulated concrete forms (ICF).

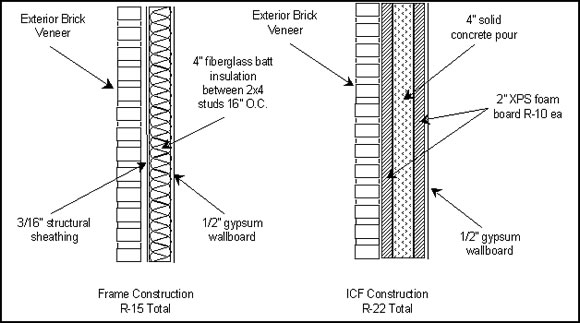

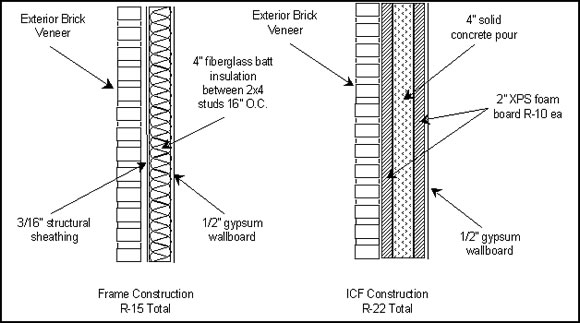

Each home was tested to determine building airtightness and

the amount of duct leakage. Table 1 shows test results and

other relevant building details. Figure 2 illustrates wall

construction for each home type.

Figure 1. Two Home Models

Figure 1. Two Home Models

According

to conventional wisdom and manufacturer’s claims, the

ICF homes should benefit from a higher and more consistent

level of thermal insulation as well as greater airtightness

wherever insulated concrete forms replace wood framing. The

envelope airtightness measurements in Table 1 (CFM50 and ACH50)

however, show that in one case the ICF home was tighter than

the frame home while in the other the trend was reversed.

This may be attributed to the fact that only the walls of

the ICF homes were constructed differently from the frame

structures, while the slab-on-grade foundation and wood-framed

roof designs were similar. Construction details at the attic

and at the junction of the first and second floors are critical

to the airtightness of these homes, as is the amount of duct

leakage.

Table 1. Building Construction &

Airtightness Details

| Construction |

ICF

|

Frame |

ICF |

Frame |

| Model |

E2051 |

E2051 |

E50 |

E50 |

| Floor Area (ft2) |

3,767 |

3,767 |

2,861 |

2,861 |

| Heat Pumps 1st/2nd

fl. |

5 ton /4 ton |

5 ton / 4 ton |

4 ton / 2.5 ton |

4 ton / 2.5 ton |

| Glass/Floor Area |

18% |

18% |

13.5% |

13.5% |

| Attic Radiant Barrier |

No |

Yes |

Yes |

Yes |

| Exterior Brick Color |

Red w/Black Tint |

Red |

Red w/Pink Tint |

Red |

| CFM50 |

2,701 |

3,105 |

2,632 |

2,426 |

| ACH50 |

4.3 |

5.0 |

5.6 |

5.1 |

| CFM25 total |

620 |

742 |

602 |

674 |

| CFM25out |

268 |

407 |

296 |

385 |

Occupancy

|

6 |

4? |

4 |

4 |

Notes:

- All homes are 2-story with the front facing north

- All windows are double pane, clear glass, aluminum frame,

U=0.81.

- All attics have R-30 blown insulation.

- SEER 12 Heat pumps were designed to run until the outside

temperature reached 47°F after which natural gas backup

heat came on. (no electric strip heat) |

Data

Collection And Analysis

Remote

data loggers collected hourly readings of indoor and outdoor

temperature, relative humidity, furnace runtime fraction,

total building electrical energy and HVAC energy use. Data

were recorded from January through August 2000.

Isolating cooling energy use from the measured HVAC energy

data provided the most useful and straightforward comparison.

Analysis of heating energy use was complicated by the use

of electric heat pump units backed up by a gas furnace. Consequently,

heating control strategies were not consistent between homes.

To

assess the cooling energy difference between the frame and

ICF homes the average daily indoor to outdoor temperature

difference (delta T) was plotted against the total daily cooling

energy use. All hours between Jan 1 and Aug 23 (the last full

day of data) were used in this analysis but only the hours

where the ambient temperature was above 65°F are included.

This allowed the isolation of those hours in which cooling

is taking place regardless of the time of year. In some cases

only a few cooling hours from a given day were included, while

in others all 24 hours were used. The average daily indoor

temperatures (IDT) were derived from the same hours when ambient

temperature was

Figure 2. Frame and ICF Wall Construction Details

Figure 2. Frame and ICF Wall Construction Details

above

65ºF. Indoor temperatures were recorded hourly at the

return plenum on each floor

and averaged together.

Normalized

Cooling Energy

In comparing both pairs of homes it was found that the ICF

buildings consistently used less miscellaneous energy (lights,

appliances, etc.) than the frame structures. While no attempt

was made to monitor or survey these energy end uses, they

could be isolated by subtracting HVAC energy from total building

energy use. Reducing the energy data of both frame homes provided

a more conservative comparison since much of the miscellaneous

energy use would be added to the home in the form of heat

that the air conditioner must then remove. Water heating energy

was not a factor here because it was provided by natural gas,

however the units were located in the conditioned space.

To normalize the comparison, the daily cooling energy in each

frame home was reduced by subtracting the difference in miscellaneous

energy between each ICF and frame home pair while factoring

in the COP of the air conditioning equipment (Equation 1).

Figures 3 and 4 show the collected data after this adjustment

and the resulting trend lines.

Equation 1. Normalized Frame Cooling

Energy

(Cooling kWh)frame = (Cooling kWh)frame

– [(Misc.kWhframe – Misc.kWhICF)

/ COPAC]

Figure 3. Normalized Energy Cooling Comparisons for Model

E50.

Figure 4. Normalized Energy Cooling Comparisons for Model

E2051.

Duct

Leakage Impact

Analysis of the measured data was also complicated by the

fact that, while the duct systems in each model were the same,

both ICF homes had tighter ducts than their frame counterparts

(see CFM25 in Table 1). Since this random variation would

favor the ICF homes, DOE2 simulations were performed to estimate

the impact. Using the E50 model home and TMY2 weather data

for Fort Worth, Texas; DOE2 simulations were performed with

a 76ºF setpoint. Results showed that increasing the duct

leakage in proportion to that found in Table 1 (CFM25out)

increased cooling energy use by about 4%. This then was added

to the ICF energy use in the final comparison below.

Measured

Seasonal Cooling Savings

Including adjustments for differences in miscellaneous energy

use and duct leakage, the measured data shows that, in both

models, the ICF home used less cooling energy than the home

built with conventional frame construction. Measured savings

of ICF construction over frame during the Dallas cooling season

are shown in Table 2. These values were derived from the linear

fit equations of Figures 3 and 4 as detailed in the Table

2 notes. Note that the final savings values in Table 2 were

decreased 4% to account for duct leakage differences as described

above.

Table 2. Measured Seasonal Cooling

Savings – ICF over Frame Construction

|

Type |

Slope |

Intercept |

Energy(kWh) |

Cost |

Savings |

Adj. Savings |

E2051(3,767 ft2) |

Frame |

1.486 |

19.71 |

4,448 |

$356 |

22.9% |

18.9% |

ICF |

1.351 |

13.90 |

3,429 |

$274 |

|

|

E50(2,861 ft2) |

Frame |

0.999 |

12.41 |

2,862 |

$229 |

20.8% |

16.8% |

ICF |

0.932 |

8.95 |

2,268 |

$181 |

|

|

Notes:

- Energy = [slope x (82.3 – 76) + intercept]

x 153

Where: |

82.3 = average summer ambient

temperature (ºF) |

| |

76.0 = average cooling setpoint (ºF) |

and |

153 = Dallas cooling season (May 1 through

September 30) |

- Frame home energy was reduced in Figures 3 &

4 to account for differences in miscellaneous energy

use

- Final savings values were reduced 4% to account

for duct leakage differences

- Utility rate of $0.08/kWh used to obtain cost savings

|

Occupant

Impacts

Occupant activity and homeowner habits can have a major impact

on residential energy use. Each of the four homes had at least

4 occupants (E2051 ICF home had 6 occupants). No other measure

of occupancy or occupant activity was recorded during the

study period.Two sources of occupant impacts were factored

out of the measured data. One by describing HVAC energy use

in terms of the difference in temperature across the building

envelope, which helps account for thermostat settings, and

the other by accounting for the difference in miscellaneous

energy use between each home pair. Some examples of occupant

activity that could not be accounted for include:

- The

level of interior shade usage

- The

amount of outdoor air allowed to enter the home

- Moisture

released inside the home by cooking and cleaning activities

-

Long-term interior door closure in rooms where insufficient

return air pathways exist

Wall

Solar Absorptance and Radiant Barriers

Despite

efforts to build each pair of homes with identical construction

except for the wall assemblies, two oversights existed –

exterior brick color differed between each home pair and an

attic radiant barrier was absent in one of the ICF homes.

The solar absorptance level of exterior walls can have a measurable

effect on the space cooling load. This effect is even more

pronounced in two-story homes where the wall surface area

is much greater than with single story construction and where

roof overhangs are less beneficial. Brick colors for the four

homes are described in Table 1 and the two pictures visually

show the difference. In the Model E2051 comparison, the frame

home had the lighter (more favorable) brick color, whereas

the ICF home had the lighter color in the E50 model comparison.

Three of the homes had roof decking with radiant barrier laminated

to the underside to reduce radiant heat transmission to the

second floor space. The model E2051 ICF home however did not

have this benefit and received a greater cooling load as a

result.

DOE2

Simulation Analysis

One

set of matched-pair homes (Model E50, Frame & ICF) was

analyzed using DOE2 simulation software to corroborate the

measured data results. The software called EnergyGauge USA®

(Parker et al. 1999), provides an input interface for performing

hourly computations with the DOE2.1E simulation engine. Annual

simulations were performed using the TMY2 weather data for

Fort Worth, Texas.

A rough comparison of the measured data with the TMY2 data

set (Table 3) shows that the weather was slightly warmer in

2000 than the typical meteorological year. Cooling degree-days,

which may approximate energy use, were 13% higher during the

data collection period from January through August. The average

ambient temperature from May through August was also higher

in the collected data (82.3 ºF) versus the TMY2 data

for the same period (79.8 ºF).

Table 3. Comparison of Measured

vs. TMY2 Weather Data

|

Measured Data (2000) |

Ft. Worth TMY2 Data |

Cooling Degree-Days (Jan –

Aug) |

2,225 |

1,939 |

Average Seasonal Summer Temperature

(May – Aug) |

82.3 ºF |

79.8 ºF |

The

computer simulations were used for two purposes: (1) Authenticate

the measured savings by comparing it with DOE2 models of frame

and ICF homes in their as-built condition, and (2) Provide

estimated savings of ICF over frame with identical construction

except for the makeup of exterior walls. The variation in

brick cladding color on each home pair was expected to have

a significant impact on the cooling energy use (Parker et

al. 2000). Ideally, solar absorptance would have been measured

for the actual bricks used in each home, instead estimates

taken from Table 4 were used in the simulations (BIA 1988).

Table 4. Absorptivity of Brick

| Brick Color |

Absorptance |

| Flashed (Blue) |

0.86 – 0.92 |

| Red |

0.65 – 0.80 |

| Yellow or Buff |

0.50 – 0.70 |

| White or Light Cream |

0.30 – 0.50 |

Source: Brick Industry

Association. Technical Notes 43D |

Authentication

of Measured Savings

DOE2

simulations of the model E50 frame and ICF homes were performed

with identical inputs except for brick color, thermostat setting,

building leakage and duct leakage. Input values and final

results are shown in Table 5. The simulations showed a savings

of only 13% as compared with the 17 to 19% found in the measured

data after adjusting for duct leakage differences in both

data sets. Note that the 17 to 19% savings determined from

the measured data was a seasonal cooling estimate for the

period from May through September, while the 13% savings found

in the simulation results is taken from cooling energy use

for the entire year. Although confidence in the measured results

is reduced due to the small sample size, the DOE2 simulations

support the measured analysis.

Table 5. DOE2 Inputs and Results – As-Built

Simulations

| Construction |

Absorptance |

Cooling Setpt |

ACH50 |

Qn |

Cooling Energy |

Savings |

Adj.Savings |

| ICF |

0.55 |

75F |

5.6 |

0.105 |

6,200 kWh |

15.90% |

12.90% |

| Frame |

0.88 |

76F (prog) |

5.1 |

0.135 |

7,375 kWh |

|

|

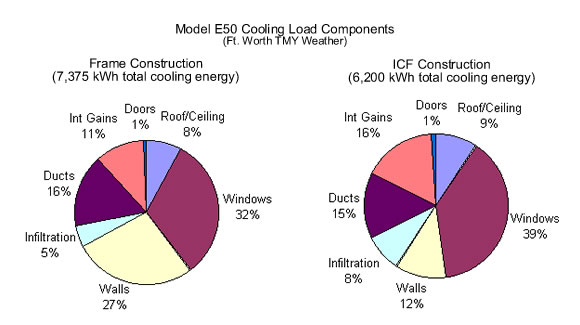

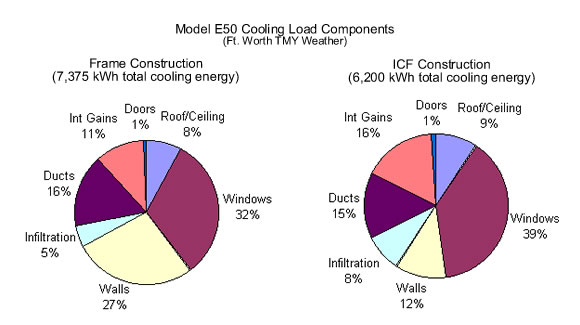

Annual

cooling load distributions were also derived from the as-built

simulation set (AEC 1992). The pie charts in Figure 5 represent

the cooling load components in each home as constructed and

tested including the differences found (brick color, thermostat

setting, building and duct leakage). Although internal gains

differed in the monitored homes, they are held constant here.

The charts show the strong impact of changing the wall construction

and absorptance of the brick cladding (solar absorptance of

0.55 for ICF home and 0.88 for frame home).

Figure 5. E50 Cooling Loads - As-built Comparison

Ideal

Comparison of ICF and Frame Construction

Another

set of DOE2 simulations were performed with the Model E50

home to determine the value of ICF over frame when the only

difference between the homes existed in the wall construction.

In this case all other parameters were held constant including:

wall absorptance, thermostat setting, building airtightness

and duct leakage. As shown in Table 6, the 2-story ICF home

saves about 13% in annual cooling energy over a similar frame

home. In another 2-story home simulation study (Gajda, 2001)

with many similar characteristics to the E50, ICF construction

saved 15% over frame in the Dallas climate. Gajda’s

value included both heating and cooling energy use however

and brick cladding was not present in either wall design.

Table 6. DOE2 Inputs and Results

– Ideal Comparison

Construction |

Absorptance |

Cooling Setpt |

ACH50 |

Qn |

Cooling Energy |

Savings |

ICF (R-20) |

0.7 |

78F |

5 |

0.105 |

5,206 kWh |

12.90% |

Frame (R-13) |

0.7 |

78F |

5 |

0.105 |

5,980 kWh |

|

Notes: Differences in DOE2 input deck

were limited to wall construction properties as detailed

in Figure 2

Qn represents duct leakage as a percent of floor area

(Qn=CFM25out/floor area) |

Figure 6 illustrates the annual cooling load

distributions (AEC 1992) when comparing frame and ICF homes

that are identical except for their wall construction. These

results give an estimate of the true impact of only changing

the wall construction while holding all other parameters

constant.

Figure 6. E50 Cooling Loads – Ideal Comparison

Conclusions

Measured

data collected in two nearly matched-pair homes shows that

insulated concrete form (ICF) construction can save 17 to

19% over the cooling season with two-story homes in the North

Texas climate. Adjustments to the measured data were made

to compensate for differences in miscellaneous energy use

(e.g. lights & appliances), and duct leakage. Differences

not quantified here included occupant impacts, exterior wall

color (or absorptance) and the absence of an attic radiant

barrier in one of the four homes.

In addition to analyzing the measured data, two sets of DOE2

simulations were performed. An initial comparison of ICF and

frame homes modeled in their as-built condition was followed

by a comparison of homes modeled with identical features except

for wall construction. Both analyses showed a 13% annual cooling

energy savings for ICF over frame construction. This result

is comparable to a similar simulation study (Gajda 2001) of

a two-story home in the Dallas climate, which saved 15% annually

on both heating and cooling.

Relative cooling savings of ICF versus frame construction

would be smaller in single story homes due to smaller wall

areas. Two-story construction makes up 33% of US housing (DOE/EIA

1995), with single story being much more common. Cooling energy

savings on single story construction could amount to only

half of that found in this study.

Further research is needed to more precisely quantify the

energy benefits of insulated concrete form homes. Such research

should compare homes that are identical in every aspect except

wall construction and ideally should be monitored without

occupancy or with simulated occupancy. Results of such carefully

controlled experiments and subsequent analysis by validated

hourly simulation software can provide a more accurate estimate

of the benefits of ICF construction. Any analysis of occupied

homes would require monitoring of a statistically valid (large)

sample of ICF and conventional residences.

Acknowledgments

This research was sponsored, in large part, by the U.S. Department

of Energy, Office of Building Technology, State and Community

Programs under cooperative agreement no. DE-FC36-99GO10478

administered by the U.S. DOE Golden field office. This support

does not constitute an endorsement by DOE of the views expressed

in this report.

The authors appreciate the encouragement and support from

George James, program manager in Washington DC and Keith Bennett,

project officer in Golden CO. Special thanks also go to Randy

Luther of Centex Homes who made this study possible. His support

and encouragement are greatly appreciated.

References

Architectural Energy Corporation (AEC). 1992. Engineering

Methods for Estimation Inputs of Demand Side Management Programs.

Palo Alto, CA. EPRI TR-100984, Volume1 pg. 2-28 through 2-31.

Electric Power Research Institute.

Brick Industry Association (BIA). 1988. Technical Notes 43D

- Brick Passive Solar Heating Systems Part 4 - Material Properties.

Reston, VA.

DOE/EIA. June 1995. Housing Characteristics, DOE/EIA-0314,

Table 3-1.Washington D.C. Energy Information Administration.

Gajda, John. 2001. Energy Use of Single-Family Houses with

Various Exterior Walls. CD026. Skokie, IL. Portland Cement

Association.

Parker, D., P. Broman, J. Grant, L. Gu, M. Anello, R. Vieira

and H. Henderson. 1999. EnergyGauge USA: A Residential Building

Energy Design Tool. Proceedings of Building Simulation '99,

Kyoto, Japan. International Building Performance Simulation

Association, Texas A&M University, College Station, TX. |

Figure 1. Two Home Models

Figure 1. Two Home Models Figure 2. Frame and ICF Wall Construction Details

Figure 2. Frame and ICF Wall Construction Details