- Air Handler Air Tightness Study

To determine the impact of air handler location

on heating and cooling energy use, researchers measured the

amount of air leakage in air handler cabinets, and between

the air handler cabinet and the return and supply plenums.

To assess this leakage, testing was performed on 69 air conditioning

systems. Thirty systems were tested in the 2001 and 39 in

2002. The 69 systems were tested in 63 Florida houses (in

six cases, two air handlers were tested in a single house)

located in seven counties across the state - four in Leon

County in or near Tallahassee, 17 in Polk County, three in

Lake County, 13 in Orange County, one in Osceola County,

two in Sumter County, and 29 in Brevard County. All except

those in Leon County are located in central Florida. Construction

on all houses was completed after January 1, 2001, and most

homes were tested within four months of occupancy.

In each case, air leakage (Q 25) at the air handler and

two adjacent connections was measured. Q 25 is the amount

of air leakage which occurs when the ductwork or air handler

is placed under 25 Pa of pressure with respect to its surrounding

environment. Q 25 also can be considered a measurement of

ductwork perforation.

To obtain actual air leakage while the system operated,

it was necessary to measure the operating pressure differential

between the inside and outside of the air handler and adjacent

connections. In other words, it was necessary to know the

perforation or hole size and the pressure differential operating

across that hole. By determining both Q 25 and operating

pressure differentials, actual air leakage into or out of

the system was calculated.

Field Testing Leakage Parameters

Testing was performed on 69 air conditioning systems to

determine the extent of air leakage from air handlers and

adjacent connections. Testing and inspection was performed

to obtain:

- Q 25 in the air handler, Q 25 at the connection to the

return plenum, and Q 25 at the connection to the supply

plenum.

- Operating pressure at four locations - the return plenum

connection, in the air handler before the coil, in the

air handler after the coil, and at the supply plenum connection.

- Return and supply air flows were measured with a flow

hood. Air handler flow rates were measured with an air

handler flow plate device (per ASHRAE Standard 152P methodology).

- Overall duct system and house airtightness in 20 of

the 69 homes.

- Cooling and heating system capacity based on air handler

and outdoor unit model numbers.

- The location and type of filter.

- Dimensions and surface area of the air handler cabinet.

- The fractions of the air handler under negative pressure

and under positive pressure.

- The types of sealants used at air handler connections.

- Estimated portion of the air handler

leak area that was sealed “as found.”

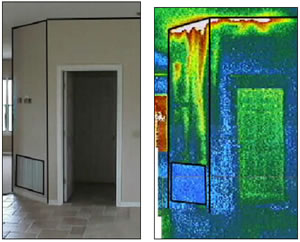

Air

Handler Leakage

|

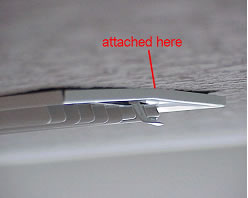

Figure

64 Thermograph

of air

being drawn from the attic to the

air handler

in a Florida house |

Leakage in the air handler cabinet averaged 20.4 Q 25 in

69 air conditioning systems. Leakage at the return and supply

plenum connections averaged 3.9 and 1.6 Q 25, respectively.

Using the operating pressures in the air handler and at the

plenum connections, these Q 25 results convert to actual

air leakage of 58.8 CFM on the return side (negative pressure

side) and 9.3 CFM on the supply side (positive pressure side).

The combined return and supply air leakage in the air handler

and adjacent connections represents 5.3% of the system air

flow (4.6% on the return side and 0.7% on the supply side).

This is a concern, when considering that a 4.6% return leak

from a hot attic (peak conditions; 120 oF and 30% RH) can

produce a 16% reduction in cooling output and 20% increase

in cooling energy use (Cummings and Tooley, 1989), and this

was only from the air handler and adjacent connections. (Figure

64)

“Total” Duct Leakage

Some important observations were made from the extended

test data in 20 houses. Total leakage on the return side

of the system (including the air handler and return connection)

was 53 cfm with weighted operating pressure on the return

side of about -100 Pa (including the air handler), operating

return leakage was calculated to be 122 CFM, or 9.7% of the

rated system air flow.

Total leakage on the supply side of the

system (Q 25s,total) was very large, at 134. The ASHRAE

152P method suggests using half of the supply plenum pressure

as an estimate of the overall supply ductwork operating

pressure, if the actual duct pressures are not known. For

the 20 systems with extended testing, supply plenum pressure

was 73.3 Pa. Based on a pressure of 37 Pa, actual leakage

should be 167 CFM or about 13.3% of the rated air flow.

To test the ASHRAE divide-by-two method, supply duct operating

pressure measurements were taken from 14 representative

systems. These averaged 35.9 Pa, compared to 65.7 Pa for

the supply plenums for those same 14 systems. For these

systems, the duct pressure was 55% of the supply plenum

pressure - making the ASHRAE method a reasonable method

for estimating central Florida home’s supply ductwork

operating pressures.

However, the ASHRAE method wasn’t reasonable for

estimating central Florida home’s return ductwork operating

pressures. For these 20 systems, 38% of the Q 25r,total was

in the air handler and 62% of the Q 25r,total was in the

return ductwork. Given an air handler pressure of -133 Pa,

a return plenum pressure of -81.5 Pa, and return duct pressure

of approximately -70 Pa, the weighted return side pressure

was approximately -95 Pa. By contrast, the ASHRAE method

predicted -41 Pa. Clearly, in systems with a single, short

return duct plenum like those commonly found in Florida,

the actual operating pressure should be greater than the

return plenum, maybe by as much as 1.2 times the plenum pressure.

Return side leakage is available on 58 of the 69 systems.

Return leak air flow (Q r,total) combined for the air handler,

return connection, and the return ductwork was found to be

152.4 CFM, or 11.8% of total rated system air flow for this

group. For this larger sample, Q r,total is considerably

greater than for the 20 houses with extended testing. These

alarming results show that even in these newly constructed

homes about 12% of return air and 13% of supply air duct

systems are leaking.

Duct Leakage to “Out”:

In 20 homes, duct leakage to “out” was

measured. (Table

38) On average, 56% of the leakage of the return ductwork

and supply ductwork was to “out.” “Out” is

defined as outside the conditioned space, including buffer

spaces like an attic or garage. The fraction of leakage

that was to “out” varied by air handler location.

For return ductwork, the proportion of total leakage to “out” is

81.4% for attic systems, 67.6% for garage, and 28.0% for

indoors. For supply ductwork, the proportion of total leakage

to “out” was in the range of 52% to 56% for

all three locations.

Table

38 Portion of duct leakage to outdoors [(Q 25,out/Q

25,total) * 100]. |

Air Handler Location |

Return |

Supply |

Entire Duct System |

Attic |

81.4% |

56.5% |

63.2% |

Garage |

67.6% |

51.7% |

56.0% |

Indoors |

28.0% |

52.6% |

37.1% |

The attic return ductwork was the most predictive

variable to “out” leakage findings. All of

the return ductwork for attic units was located in the

attic. Much of the return ductwork for other units was

located in the house. As a consequence, the energy penalty

associated with locating the air handler in the attic was

greater than indicated in the computer modeling results

in Table 39, since the modeling only considered the leakage

of the air handler cabinet and the adjacent connections,

and not the return ductwork leakage.

Table

39 Duct leakage “total” and

to “out” for three locations,

for both 25 Pa test pressure and for actual

system operating pressure. Sample size is

in [brackets]. |

|

Attic

(cfm) |

Garage

(cfm) |

Indoors

(cfm) |

Combined

(cfm) |

Test |

Total |

Out |

Total |

Out |

Total |

Out |

Total |

Out |

Q 25,r [58] |

61.9 |

50.4 |

93.3 |

63.1 |

67.8 |

19.0 |

75.7 |

44.9 |

Q 25,s [20] |

109.1 |

61.6 |

170.6 |

88.2 |

119.5 |

62.9 |

134.3 |

71.4 |

Q r [58] |

118.1 |

96.1 |

194.4 |

131.4 |

134.6 |

37.7 |

152.4 |

90.4 |

Q s [20] |

135.6 |

76.6 |

212.0 |

109.6 |

148.5 |

78.1 |

166.9 |

88.7 |

Table

39 shows that the operating supply leakage to “out” was

large for all three air handler locations, averaging 89

CFM. The average operating return leakage to “out” was

slightly larger, at 90 CFM. However, there was a large

variation between air handler locations; 96 CFM for attic

systems, 131 CFM for garage systems, but only 38 CFM for

indoor systems. From an energy perspective, the attic systems

experienced the greatest “real” energy penalties,

because all of the return ductwork and air handlers were

located in the attic. (Table 38) By contrast,

a majority of the return leakage for the garage systems

likely came from the garage (which is considerably cooler

than the attic). For indoor systems, the return leakage

to “out” most likely originated from the attic.

However, since the return leakage was so much smaller,

the energy impact was likely considerably less than both

the attic and the garage systems.

|

Figure

65 Supply

CFM25 “total” leakage versus the number

of supply registers. |

|

Figure

66 Supply

CFM25 “out” leakage

versus the number

of supply registers. |

Correlation

of Supply Duct Leaks with Number of Registers: When

analyzing the supply leakage in the extended test data, a

surprising correlation was observed. This correlation indicated

a systematic and consistent duct fabrication problem across

a wide range of air conditioning contractors. Figure

65 illustrates this correlation, showing that each supply

duct has a remarkably predictable total duct leakage. The

coefficient of determination is 0.86, indicating that 86%

of the variability in total supply duct leakage was explainable

by the number of supply registers. Figure 66 shows

a similar relationship between supply leakage to “out” and

the number of supply registers. In this case the coefficient

of determination was 0.69, indicating that 69% of the variability

in total supply duct leakage was explainable by the number

of supply registers. Note that one of the two houses with

13 registers showed considerably less leakage than expected.

In this case, supply ducts were located in the interstitial

space between floors. When the house was taken to -25 Pa,

it is probable (though not measured) that the interstitial

spaces were substantially depressurized as well, so leaks

in those supply ducts would show less air flow (i.e., less

pressure differential = less leakage air flow) and therefore

be under-represented.

The data suggest that a duct leakage problem occurs in nearly

all new homes. Researchers identified three issues that create

most of the leakage: (1) the connection of the supply register

or return grill (Figure 68), (2) the boot (supply

box) to sheet rock connection (Figure 67), and (3)

the flex duct to collar connection. The supply register or

return grill leakage typically shows as supply leakage in

the “total” test.

It usually occurs when the register or grill does not fit snugly

to the ceiling or wallboard. Issues two and three show up as

leakage to both “out” and “total.”

|

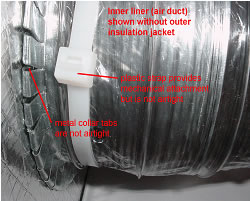

Figure 67 Flexible duct

to metal collar connection. |

|

Figure 68 Gaps at the

supply

register to drywall joint |

Figure

67 shows how flexible duct connections typically are

made. In some cases metal tape is used, but the tape wrinkles

when applied to complex angles and over bumps associated

with these connection types. Although small in size, these

cumulative wrinkles at each connection allow air to pass

through.

Computer

Modeling for Florida Energy Code Air Handler Multipliers:

FSEC

researchers performed simulations and developed air handler

multipliers for the Florida Energy Code using this study’s

simulation results. Researcher used the FSEC 3.0 model,

a general building simulation program developed in 1992.

This program provided simultaneous detailed simulations

of a whole building system, including energy, moisture,

multi-zone air flows, and air distribution systems.

In 2001, modeling had been performed to develop initial

air handler multipliers. These multipliers were based on

estimated Q 25 and duct operating pressures. At the time

of the 2001 modeling, there was essentially no data on air

handler and connection leakage. Modeling for this project

was performed again, but this time using the results of the

69 field tested homes.

The modeling inputs used in 2001 and those from the current

study are shown below. (Table 40) Note that the

same Q 25 and operating depressurization (dP) values was

used for all air handler locations, since there was essentially

no difference between the Q 25 values for attic, garage,

and indoor air handler locations when gas furnace units were

removed from the analysis.

Table

40 Air handler (AH) and connection inputs

for 2001

and current project computer

modeling.

|

|

2001 Q 25 |

AH Study Q 25 |

2001 dP |

AH Study dP |

Return connection |

8.7 |

3.9 |

-40 |

-86.1 |

AH – depressurized

portion |

48.5 |

17.6 |

-42 |

-139.1 |

AH – pressurized

portion |

9.6 |

2.8 |

43 |

106.5 |

Supply connection |

7.8 |

1.6 |

32 |

58.2 |

Total |

74.6 |

25.9 |

|

While

the Q 25 leakage for the air handler and connections was

about 65% less than earlier estimates, operating pressures

were much higher. The air handler multipliers based on the

current computer modeling results are presented in Tables

41, 42, and 43. Modeling of air handler energy use also

was performed for the air handlers located outdoors, despite

the fact that no field data was collected for outdoor units.

The modeling input parameters were the same as the other

air handler locations as shown in Table 40. Note

also that the air handler multipliers for the attic, indoors,

and outdoors are normalized to the garage, since this location

was considered the baseline. The final report for this study

can be viewed online at: http://www.fsec.ucf.edu/bldg/pubs/cr1357/index.htm.

Table

41 Florida Energy Code AH Multipliers for South Florida. |

AH Location |

Winter |

Summer |

Old |

2001 |

new |

old |

2001 |

new |

attic |

1.04 |

1.15 |

1.12 |

1.04 |

1.09 |

1.06 |

garage |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

indoors |

0.93 |

0.91 |

0.94 |

0.93 |

0.91 |

0.92 |

outdoors |

1.03 |

1.08 |

1.06 |

1.03 |

1.03 |

1.01 |

Table

42 Florida Energy Code AH Multipliers for Central

Florida. |

AH Location |

Winter |

Summer |

Old |

2001 |

new |

old |

2001 |

new |

attic |

1.04 |

1.11 |

1.08 |

1.04 |

1.10 |

1.08 |

garage |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

indoors |

0.93 |

0.92 |

0.94 |

0.93 |

0.90 |

0.92 |

outdoors |

1.03 |

1.09 |

1.05 |

1.03 |

1.02 |

1.01 |

Table

43 Florida Energy Code AH Multipliers for North Florida. |

AH Location |

Winter |

Summer |

Old |

2001 |

new |

old |

2001 |

new |

attic |

1.04 |

1.10 |

1.03 |

1.04 |

1.11 |

1.08 |

garage |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

indoors |

0.93 |

0.93 |

0.94 |

0.93 |

0.91 |

0.92 |

outdoors |

1.03 |

1.07 |

1.02 |

1.03 |

1.02 |

1.01 |

- Air Conditioning Condenser Fan Efficiency

Purpose

The purpose of this study is to develop an air conditioner

condenser fan that reduces the electric energy use of the

condensing unit (Figure 69). To accomplish this,

researchers are designing and producing more aerodynamic

fan blades and substituting smaller horsepower (HP) motors

which achieve the same air flow rates as the larger, less

efficient motors typically used.

4th

Budget Period

|

Figure 69 Air conditioning

condenser fan and diffuser. |

During

the 4th budget period, researchers developed baseline data

for the fan power use in a standard condensing unit (Trane

2TTR2036) and tested a new prototype design: “Design

A5” with five asymmetrical blades

Baseline

data included condenser airflow, motor power, sound levels,

and condenser cabinet pressures. Test results favorably

compared with the manufacturer’s test data. An experimental

set of fan blades, “Design-A5,” designed for

a 1/8 hp motor at 850 rpm was numerically created and then

successfully produced using rapid prototyping. These prototype

blades were substituted on the original condenser, and all

test measuredments were redone. Design-A5 was found to reduce

power use by 20% (40 watts) with approximately equivalent

airflow to the original condensing blade design.

5th

Budget Period

During the 5th budget period, activities included re-calibration

and improvement of the test equipment configuration, refinement

of various designs, and patent filing.

Re-calibration and Improvement of Test Equipment Configuration

The

air flow measurement equipment was re-calibrated by the

Energy Conservatory in Minneapolis in accordance with ANSI/ASHRAE

51-1985 ("Laboratory Methods of Testing

Fans for Rating."). Testing determined that the "flow

cube" could be modified with settling screens and a

flow straightener to yield a 5% absolute flow accuracy and

a 2% relative accuracy from the test equipment. Also, the

test configuration was moved indoors in order to better measure

sound and also to reduce test variability from wind-related

effects. Noise measurement protocol improved to comply with

procedures used by the air conditioning industry.

Continued Testing to Refine the Identified Condenser

Fan and Condenser Top Design

All

fans were re-evaluated after bringing the test apparatus

into compliance with ANSI/ASHRAE 51-1985 ("Laboratory

Methods of Testing Fans for Rating.") New fan prototypes “Design-D” and “Design

E” were tested as well as a diffuser for a 27" fan

and a specially prepared Electronically Commutated Motor

(ECM) provided by General Electric.

All designs were also tested with the conical diffuser with

20-27% increases in measured flow from the low rpm designs,

which use 8-pole motors. Sound measurements (Table 44) also

showed large advantages with as much as a 4 dB reduction

in fan sound level over the standard fan. The final test

prototype with diffuser and fan is shown in Figure 70.

Table

44 Sound measurements for various fan and housing

designs |

Top |

Fan |

Motor |

Flow |

Power |

Sound |

OEM/ Starburst |

OEM |

6-pole |

2170 cfm |

197 W |

63.0 dB |

OEM-Foam |

OEM |

6-pole |

2230 cfm |

198 W |

63.0 db |

Wire top |

OEM |

6-pole |

2180 cfm |

188 W |

62.0 dB |

Wire-Foam |

OEM |

6-pole |

2250 cfm |

190 W |

62.0 db |

OEM-foam |

A5 |

8-pole |

1945 cfm |

145 W |

62.0 dB |

Wire-foam |

A5 |

8-pole |

2110 cfm |

146 W |

60.0 dB |

WhisperGuard w/foam |

A5 |

8-pole |

2300 cfm |

143 W |

58.5 dB |

Presentation and Commercialization

In January, BAIHP researcher Danny Parker made a presentation

at the DOE Expert meeting on HVAC and Fans in Anaheim, California

and participated in productive meetings with Trane Corporation

in May 2004 to discuss licensing of the technology under

an existing non-disclosure agreement.

Patents Pending

U.S.

Application Serial No. 10/400,888, Provisional applications

60/369,050 / 60/438,035 & UCF-449CIP;

WhisperGuard (UCF-Docket No. UCF-458)

Key

Improvements from WhisperGuard Technology

|

Figure

70 Final

test prototype

with diffuser and fan. |

Tested Performance with Trane TTR2036 Condenser:

- Provides 46 Watt reduction in fan power (144 W vs. 190

Watts)

- Increases condenser air flow by 130 cfm (6% increase

in fan flow)

- Provides 102 W power reduction with ECM 142 motor

- Reduce ambient fan-only sound level by 4-5 dB

- ECM motor allows lower fan speeds for ultra-quiet night

operation, higher flows for maximum capacity during very

hot periods (temperature based control)

- Attractive hi-tech diffuser appearance

Key

Technologies Employed

- High efficiency 5-bladed asymmetrical fan moves air quietly

at lower fan speeds

- Diffuser top for effective pressure recovery increasing

air flow at slow speed ranges

- Conical center body reduces exhaust swirl

- Acoustic

sound control strip to reduce tip losses and control tip

vortex shedding

-

Fenestration Research

American

Society of Heating, Refrigerating, and Air Conditioning

Engineers (ASHRAE) Technical Committee :

In 2002, BAIHP researchers wrote a statement of work for

the development of a methodology to calculate solar spectral

distributions incident on windows for various sun positions

and atmospheric conditions. ASHRAE approved the project and

sent it out for bid. Completion of this work project should

make it much easier to determine the true solar heat gain

through spectrally selective fenestration systems for varying

atmospheric conditions and solar altitude angles.

Calorimetric Measurements of Complex Fenestration Systems

FSEC’s

research calorimeter will be used both indoors with the

FSEC Vortek solar simulator and outside under natural solar

radiation, on its Sagebrush solar tracker, for window solar

heat gain experiments. The results of this testing will

offer a way to test the solar gain properties of complex

and other non-standard fenestration options for industrialized

housing, such as exterior and interior shades and shutters,

and those placed between the panes of double pane windows.

Sagebrush Solar Tracker

The

computer program running the calorimeter, the Sagebrush

tracker, and both together is complete. It contains a user-friendly

graphic interface and offers a wide variety of experimental

opportunities. There are many channels for adding additional

temperature sensors and the calorimeter/tracker can be

operated with either the sun as a source - in a variety

of tracking modes - or with FSEC’s Vortek solar simulator.

To

conduct outdoor testing, the Neslab chiller must be connected

to the flow meter, the temperature sensors to the calorimeter,

and the calorimeter mounted on the tracker. The Sagebrush

tracker now is functional, responding properly to commands

sent from the computer, rotating in altitude, and azimuth

and stopping when the limit switches are encountered. A telescopic

sight and level for positioning it outdoors in the proper

orientation for accurate solar tracking has been designed

and is near fabrication completion.

|

Figure 71 Side view

of calorimeter before

it was mounted on the Sagebrush

Tracker. |

The

Neslab chiller and remote controller have been connected

to a Gateway laptop computer and a RS-485 serial interface

card necessary to operate the calorimeter has been installed.

Researchers can now send commands and receive data from the

chiller. Although the calorimeter is designed to work directly

with the existing FSEC hydronic loop used for testing solar

collectors, the Neslab will give an independent, standalone

capability to the calorimeter. (Figure 71)

The water flow meter purchased for measuring the flow into

the calorimeter has been successfully connected to the Agilent

(HP) 34970A data acquisition system and its measurements

were incorporated into the calorimeter operating program.

Temperature sensors also successfully connected to the data

acquisition system, are reading properly, and have been incorporated

into the calorimeter program. The program has coding to include

a number of additional temperature channels once the temperature

probes have been received and installed in the calorimeter.

Another 20-channel input card is being purchased for the

Agilent, to permit additional temperature readings. Knowing

the flow rate and temperature difference, the heat delivered

to the water by the calorimeter can now be accurately determined.

Now that all portions of the system are operational, researchers

will configure the outdoor system, verify, and begin testing

in Year 5.

Vortek Solar Simulator

In

2003, the Vortek Simulator was fired up and operated reliably

on the calorimeter testing with FSEC’s solar

collector test apparatus. As expected, a few computer and

other problems delayed initial data collection by a couple

of days. However, these problems were corrected and testing

proceeded normally.

During

testing, the calorimeter was connected to the existing

facility’s hydronic loop, which was

developed over a period of years to a temperature stability

of 0.01 degrees centigrade. The irradiance level measured

about 820 watts per square meter over an aperture of 0.557

square meters. The calorimeter was tested as though it

were a flat plate collector, to obtain its efficiency curve.

This was used to infer the thermal losses and solar heat

gain coefficient of the eighth inch clear single pane of

glass used for the test. The nominal wind speed was set

by the laminar blower to five miles per hour. The coolant

flow was run at levels of 0.2, 0.5, and 1.0 gallons per

minute (GPM), and at varying inlet temperatures.

For all test runs, steady state conditions were established

by observing the outlet temperature in a real-time plot as

equilibrium was approached. During periods of non-equilibrium,

the recorded data was used to measure the first-order system

time constant, a function of the flow rate. The calorimeter

time constant varied from 1.5 minutes at 1.0 GPM to 6.9 minutes

at 0.2 GPM. These time constants were obtained by blocking

the incident beam and watching the decay in outlet temperature.

Skylight Dome Transmittance

Researchers completed work on the skylight dome transmittance,

adding a spherical shape to the cylindrical one previously

used. The ray tracing programming was changed to eliminate

reflection of rays approaching the dome from the inside,

for comparison with the analytical model, which does not

yet include internal reflections. The difference between

the two computational approaches, at a 30 E solar zenith

angle is 1.7%, considered acceptable for rating skylight

performance.

With both cylindrical and spherical dome models, transmittance

at large solar zenith angles above 60 is substantially greater

than for a horizontal flat plate. This is because most of

the rays incident on the dome and entering the skylight are

incident on the dome close to perpendicular, where dome transmittance

is highest.

Energy Gauge USA and Energy Gauge FlaRes

BAIHP mapped a table of window and shade characteristic

simulations that could be run with these two programs. These

runs will be used to determine the energy use of various

fenestration options for Florida residences and to guide

the preparation of instructional materials.

Florida Market Transformation

From the beginning of the BAIHP program, researchers have

provided technical background information and support to

the Alliance to Save Energy and the Efficient Windows Collaborative

to promote the sale and installation of energy efficient

fenestration in hot climates (such as Florida) and other

areas for both conventional and industrialized homes. BAIHP

also provides advice, technical information, and educational

information to energy companies regarding window energy performance.

National Fenestration Rating Council (NFRC) Technical

Committee

In 2002, BAIHP presented a final report at a Task Group

meeting in Houston, on the NFRC- funded work to develop a

draft standard practice for the rating of tubular daylighting

devices. That project is now complete.

In

2001, BAIHP researchers performed a number of ray traces

on a highly reflective cylinder of varying lengths, using

the trace results to determine the cylinder’s transmittances

for different interior surface reflectivities (from 90% to

100%). These results generated a “default table” for

determining the transmittance of this tubular daylighting

component. Using simplified assumptions, and then multiplying

the tube transmittance by the top and bottom dome transmittance

results, researchers determined the total transmittance for

a chosen sun angle. Based on the findings, BAIHP provided

NFRC and the industry with a list of suggested research projects

to test and develop this methodology further. One of these

submitted projects was sent out for bid by ASHRAE in Year

4 and is expected to begin in Year 5.

Tubular Daylighting Device SHGC and VT Value Calculations

Following

a request from the TDD industry, a sequence of operations

and a new computer program were written to access the Window

5 glazing database and obtain from it the spectral transmittance

and front and back reflectance data for any sheet of glazing

in that database which might be used in making the top

dome of a tubular daylighting device. This permits determination

of the input parameters needed to run TDDTrans. The computer

program was posted for free download and is available by

clicking on http://fsec.ucf.edu/download/br/fenestration/software/TddTrans-Beta/TDDTrans.exe.

Access sequence:

- Download and run the Optics 5 program.

- Select the glazing to be used in the tubular daylighting

device.

- Export its spectral data file as a standard ASCII text

file.

|

You

are here:

You

are here: