|

|

|

| Reference

Publication: McIlvaine, Janet,

David Beal, Neil Moyer, Dave Chasar, Subrato Chandra.

Achieving Airtight Ducts in Manufactured Housing. Report

No. FSEC-CR-1323-03. |

|

|

|

| Disclaimer:

This report was prepared as an account of work sponsored by

an agency of the United States government. Neither the United

States government nor any agency thereof, nor any of their

employees, makes any warranty, express or implied, or assumes

any legal liability or responsibility for the accuracy, completeness,

or usefulness of any information, apparatus, product, or process

disclosed, or represents that its use would not infringe privately

owned rights. Reference herein to any specific commercial

product, process, or service by trade name, trademark, manufacturer,

or otherwise does not necessarily constitute or imply its

endorsement, recommendation, or favoring by the United States

government or any agency thereof. The views and opinions of

authors expressed herein do not necessarily state or reflect

those of the United States government or any agency thereof. |

|

|

Achieving

Airtight Ducts in

Manufactured Housing |

|

|

|

|

|

|

Florida

Solar Energy Center (FSEC) |

|

| |

| Publication

Index:

|

| Figure

4.

No mastic on return duct in plenum serving packaged heating

and cooling unit. Mastic used elsewhere in the plenum

and throughout house. |

| |

|

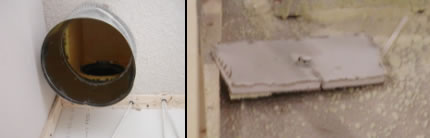

| Figure

5. Above Misalignment of round duct to round

cutout. Arrow shows where components should mate. Below

Misalignment/insufficient connection surface at round

duct collar to rectangular duct. |

|

Challenges

to Achieving Duct Tightness Recommendations

After

BAIHP makes recommendations in a Trip Report, the factory

staff work out solutions to the problems identified. Often,

problems identified during a test can be quickly located in

other duct systems on the production line. The problems most

often encountered mirror those identified by BAIHP staff during

field work with moisture and air flow damaged manufactured

homes (Moyer, et al, 2001). The most commonly encountered

challenges include:

- Leaky

supply and return(Fig. 4) plenums

- Misalignment

of components (Figure 5), for example, floor boots not reaching

or not being lined up with trunk ducts (in-line floor ducts)

- Free-hand

cutting of holes in duct board and sheet metal without templates,

often with “home made” tools or utility knives

(Fig. 6), for example, a hole for a crossover collar not

being round creates a poor collar connection, holes in trunk

duct for floor boots cut too large for floor riser, creating

a hard-to-seal hole)

- Insufficient

connection area at joints (Fig. 5, bottom), for example,

supply plenum and drop-out collar that are same dimension

as the trunk duct.

-

Mastic applied to dirty (sawdust) surfaces

-

Insufficient mastic coverage

-

Mastic applied to some joints and not others

-

Loose strapping on flex duct connections

-

Incomplete tabbing of fittings (Fig. 7, bottom)

-

Poor tape application

|

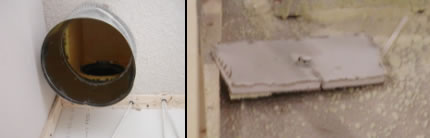

| Figure

6. Left Holes cut free hand do not mate well

with duct system components. Note round duct is jammed

into an oval shaped cut out. Right Imprecise rectangular

cutout for ceiling register creates poor joint. |

Continue

to Achieving Duct Tightness Recommendations >> |

|

|